Things To Check Before Buying High Mast Light Pole

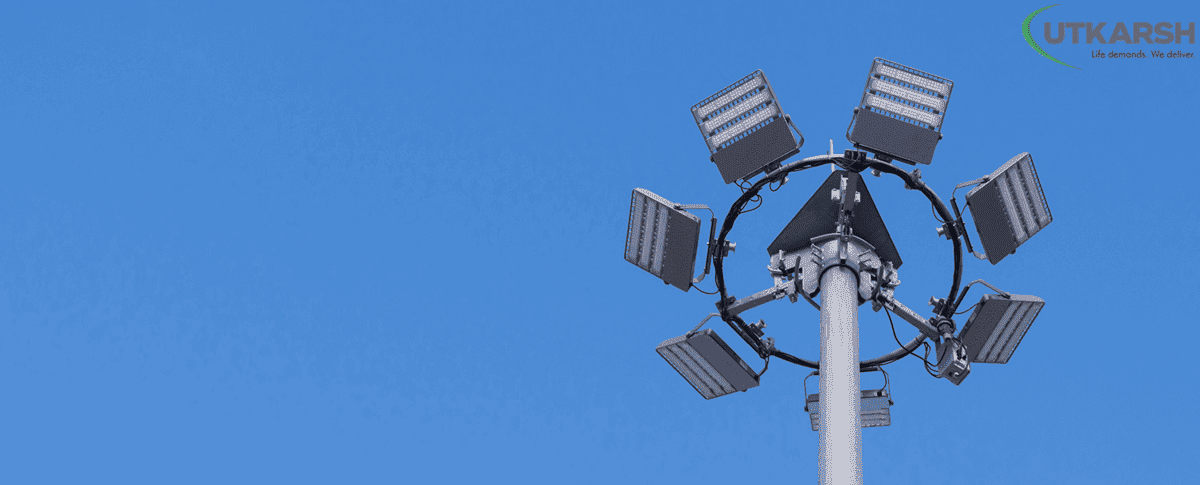

Typically, a High Mast Light Pole is used to illuminate a roadway or a recreational field. It's utilized in places where a lot of light has to be spread out across a wide area. The pole on which the lighting is placed is typically 30 m (98 ft) or higher, and the illumination consists of a luminaire ring around the pole with one or more separate lighting fixtures attached to it.

The high mast's height ranges between 50 and 150 feet. The High Mast Light Pole is presently the most successful in illuminating vast outdoor areas due to its ability to produce greater brightness levels (highways, railway yards, parking lots, airports, seaports, stadiums, etc.)

Things to consider before buying High Mast Light Pole

Some of them are technical, but here, attention to detail is a must-

Mast Dynamic Loading

For coastal locations, the mast structure must meet the requirements of IS: 875/1987 (Part III) and be capable of withstanding an assumed maximum reaction caused by wind speeds of 180 km/h (50 m/sec; three-second gust) for inland locations, and 225 km per hour (62.5 m/sec; three-second gust) for coastal locations. The mast must have a minimum design life of 25 years. The technique of construction will dampen wind-excited oscillations, and the associated stresses will be adequately accommodated.

You May Like - Things to Consider Before Selecting the Right Pole Lights

Structure

It is required that the High mast has a 20-sided polygonal cross-section with a continuously tapered cross-section, providing a pleasant and attractive look and dependable performance and service. It is required that for wind speeds up to 50 m/sec, the mast's top and bottom A/F dimensions are 200mm and 540mm, respectively, and 200mm and 610mm, respectively, for winds up to 62.5 m/sec. When the wind speed is 50 m/sec, the plate thickness is 5 mm on the bottom and 4 mm on the top; when the wind speed is 62.5 m/sec, the plate thickness is 6 mm on the bottom and 4 mm on the top. If the ship is going 50 mph, the mast flange should be 650 millimeters in diameter and 30 millimeters thick. If the ship is going 62.5 miles per hour, it should be 730 millimeters in diameter and 30 millimeters thick.

Construction

When used in inland areas, the mast's wind resistance must be at least 180 KMPH (50 m/sec), whereas, in coastal sites, it must be at least 225 KMPH (62.5m/sec). Fabricated from BS EN 10025 or equivalent steel plates, with the minimum yield strength of 355 N/Sq.mm and silicon content in steel of less than 0.06 percent, the mast shall be cut and folded to form polygonal sections with 20 sides, then welded with an automatic submerged-arc welding machine. The steel plates shall meet the minimum yield strength requirements.

You May Like - Applications and Benefits of Using High Mast Lighting

The mast must not have any onsite welding or bolted joints. Only one longitudinal weld is required on the High Mast Shaft, with no circumferential weld. The overlap distance must be at least 1.5 times the diameter of the hole at which it will be drilled.

An unlaminated and unincluded full-penetrated flange must be supplied on the mast. The base flange's welded connection must be completely developed to meet the section's strength requirements. The base flange must have additional gussets between the bolt holes. The whole manufactured mast must be hot-dipped galvanized on both the inside and outside. The mast's deflection must be kept to less than a quarter of its design height in winds of two-thirds the design speed.

Considering these few specific dynamics will help you narrow down the course of consideration before buying a high mast pole.