HDPE pipes, or High-Density Polyethylene pipes, are widely used for various applications due to their durability, flexibility, and resistance to corrosion. These pipes are made from high-density polyethylene, a strong and lightweight material that offers numerous benefits over traditional piping amd advanced options. One of the key advantages of HDPE pipes is their ability to withstand harsh environmental conditions, making them ideal for water supply, gas distribution, and sewage systems. Overall, the advantages of HDPE pipes combined with the reliability offered by HDPE pipes manufacturers make them a top choice for modern infrastructure projects.

Our high quality HDPE pipes & Fittings offer excellent functionality across multiple industries, like oil & gas, mining, chemical & others. With smooth surface finish, anti-corrosion assistance, and top-notch mechanical strength, these pipes facilitate the transportation of different substances, like potable water, chemicals, slurries, wastewater, compressed gases, and even select hazardous wastes. When exploring the benefits of HDPE pipes, it becomes clear why they are a preferred choice in demanding industrial applications.

Manufactured in adherence with stringent quality and functionality standards, our HDPE pipes are usable in ground, surface, buried and floating applications. As a trusted name among HDPE pipe manufacturers in Kolkata, be it municipal or industrial infrastructure projects, Utkarsh Pipes and Fittings is the go-to partner for all customer needs.

HDPE Pipes: The Backbone of Modern Infrastructure by HDPE Pipe Manufacturers in Kolkata

Utkarsh Pipes and Fittings ranks among the top HDPE pipe dealers in Kolkata. Designed as an efficient and cost-effective solution, our HDPE Pipes & Fittings are ideally suited for diverse projects, including municipal, water supply, irrigation (major, minor), treatment plants, sprinkler & drip irrigation, industrial, marine, mining, landfill, duct, and other agricultural applications.Our high quality HDPE pipes & Fittings offer excellent functionality across multiple industries, like oil & gas, mining, chemical & others. With smooth surface finish, anti-corrosion assistance, and top-notch mechanical strength, these pipes facilitate the transportation of different substances, like potable water, chemicals, slurries, wastewater, compressed gases, and even select hazardous wastes. When exploring the benefits of HDPE pipes, it becomes clear why they are a preferred choice in demanding industrial applications.

Manufactured in adherence with stringent quality and functionality standards, our HDPE pipes are usable in ground, surface, buried and floating applications. As a trusted name among HDPE pipe manufacturers in Kolkata, be it municipal or industrial infrastructure projects, Utkarsh Pipes and Fittings is the go-to partner for all customer needs.

- Total solutions in PE Piping Systems

- Lightweight pipes, with 50-100 years service life

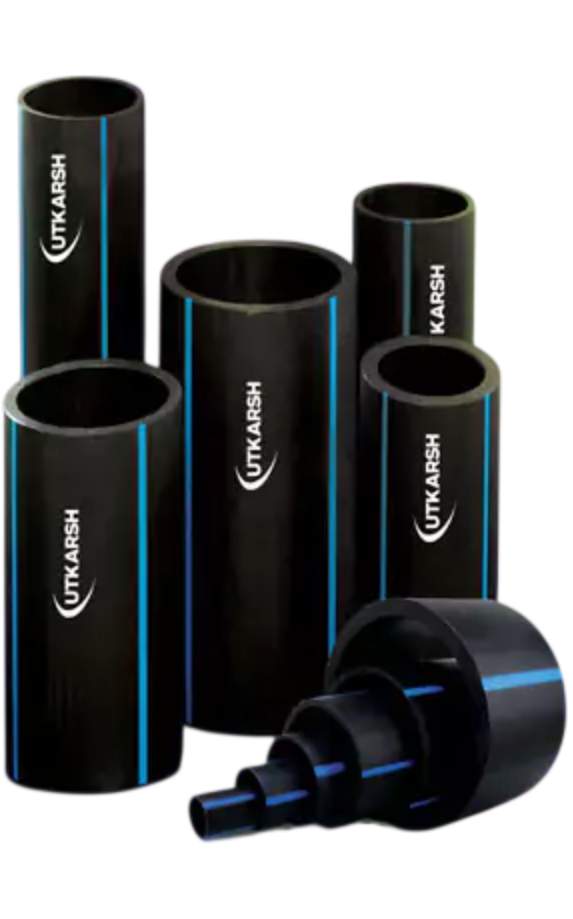

- Available in sizes from 20 mm to 315 mm

- Adherence with national and international specifications

-

44000

Plant Area

-

68000

Production Capacity

-

5000

Ready Stock

Product Specifications

Discover the detailed product features & specifications of our HDPE pipes & Fittings, ensuring top-notch performance and reliability for diverse applications.

Check out the comprehensive technical details of our HDPE pipes & fittings, designed for exceptional durability and superior performance in various environments.

- High C' value ensures efficient transportation of fluids, gases, and chemicals.

- Excellent SCGR (Slow Crack Growth Resistance) for long-lasting performance infrangible performance.

- Longer delivery lengths reduce the need for fittings.

- Adheres to all relevant BIS standards.

- Life expectancy ranges from 50 to 100 years.

- 'C' value of 150 throughout its life.

- Mirror-like smooth inner surface for superior flow characteristics.

- Its light weight ensures easy handling & installation.

The key standard specifications of our HDPE pipes make sure that they meet the highest standards of performance and reliability.

- Superior Corrosion and Abrasion Resistance for Lasting Durability

PVC HDPE pipes offer excellent corrosion and abrasion resistance, ensuring durability over time while retaining their chemical properties for potable water, fluids, gases, and other chemical substances. As leading HDPE pipes manufacturers, we provide solutions that withstand harsh conditions, extending the lifespan of your infrastructure. - Incrustation and Scale Formation Resistance

One of the significant advantages of HDPE pipes is their resistance to incrustation and scale formation. HDPE pipes manufacturers design these pipes to maintain a smooth internal surface, reducing blockages and improving flow efficiency. - Leak-Free and Abrasion-Resistant Fittings

Our HDPE pipe fittings are engineered to be leak-free and abrasion-resistant, offering a reliable and secure connection. HDPE pipes manufacturers focus on producing high-quality fittings that ensure your piping system's integrity. - Available in Various Diameters for Versatile Applications

HDPE pipes are available in diameters ranging from 20mm to 315mm, catering to a wide range of applications. This versatility is one of the key advantages of HDPE pipes, allowing them to be used in diverse industries. - Manufactured in PE 63, PE 80, and PE 100 Product Grades

As trusted HDPE pipes manufacturers, we produce pipes in PE 63, PE 80, and PE 100 product grades. These options provide flexibility in choosing the right pipe strength and performance level for your specific needs.

Explore the exceptional advantages of HDPE pipes, crafted for unmatched performance, durability, and reliability - setting the benchmark among HDPE pipe manufacturers in Kolkata.

- Exceptional Chemical Resistance

HDPE Pipes & Fittings are engineered to withstand corrosive fluids and slurry, making them ideal for demanding and extreme environments. These pipes ensure longevity and reliability, which is why leading HDPE pipe dealers recommend them for the transportation of aggressive chemicals. - Lightweight and Easy to Handle

One of the key advantages of HDPE pipes is their lightweight nature. PVC HDPE pipe manufacturers design these pipes for easy handling, storage, and transportation, reducing labour costs and installation time across various projects, and enabling work even in inaccessible areas. - Superior Flexibility for Versatile Applications

Thanks to their superior flexibility, HDPE pipes & fittings are easy to install, even in challenging terrains. These advantages make HDPE pipes a top choice for various applications, including irrigation and fluid transportation, while also reducing the need for fittings. - Optimal for Fluid Transportation and Irrigation

HDPE pipes are suitable for efficient fluid transportation and sprinkler irrigation systems. HDPE pipes manufacturers emphasise the advantages of HDPE pipes in these sectors due to their durability and efficiency. - Versatile Usage Across Multiple Sectors

Designed for use in agricultural, infrastructure, and industrial sectors, HDPE pipes offer unparalleled versatility. HDPE pipes manufacturers highlight the advantages of HDPE pipes for their adaptability to a wide range of applications, ensuring they meet the needs of diverse industries.

Application Areas

Manufacturing Process

From sourcing premium raw materials to precision engineering and rigorous testing, every HDPE pipe we craft reflects excellence - cementing our name among reliable HDPE pipe manufacturers in Kolkata.

-

Raw Material

Selecting high-grade polymers for optimal durability and performance in the pipe production process.

-

Extrusion

Melting and shaping the polymer into uniform pipes through precision extrusion processes.

-

Cooling

Rapidly cooling the extruded pipes to stabilise their molecular structure and enhance strength.

-

Cutting

Precision cutting of pipes to specified lengths, ensuring uniformity for operational efficiency.

-

Testing

Conducting rigorous quality checks to verify strength, dimensions, and durability under various conditions.

-

Packaging

Ensuring secure packaging to protect pipes during transportation, so they reach customers in pristine condition.