SWR Pipes and fittings are utilised in non-pressurised plumbing applications, including waste and soil transportation, non-pressurised industrial drainage, and waste discharging systems in hotels, resorts, and residential and commercial buildings. As India's leading SWR pipes and fittings manufacturer, we offer a wide range of SWR pipes that ensure efficient and seamless water supply systems.

Designed with meticulous attention to detail, Utkarsh Pipes & Fittings manufactures export-standard SWR (Soil, Waste, and Rain) pipes and fittings that ensures efficient sewerage waste applications, like soil, waste, rainwater and ventilation. Our pipes feature exceptional leak-proof gold seals which are engineered to provide a permanent and secure fit, effectively eliminating the issue of rubber rings coming out during installation. Our commitment to delivering only the best outputs of SWR pipe fittings is what sets us apart from other SWR pipes manufacturers in India. The competitive price range of our products despite compromising the superior quality of each SWR pipe makes us a partner of choice for several industrial and commercial projects throughout the country.

With the many years of expertise and technical know-how, we take immense pride in being the most trusted SWR pipes and fittings manufacturer in India and around the world. We are able to consistently exceed client expectations due to our unwavering commitment to quality and our innovation-first strategy.

Designed with meticulous attention to detail, Utkarsh Pipes & Fittings manufactures export-standard SWR (Soil, Waste, and Rain) pipes and fittings that ensures efficient sewerage waste applications, like soil, waste, rainwater and ventilation. Our pipes feature exceptional leak-proof gold seals which are engineered to provide a permanent and secure fit, effectively eliminating the issue of rubber rings coming out during installation. Our commitment to delivering only the best outputs of SWR pipe fittings is what sets us apart from other SWR pipes manufacturers in India. The competitive price range of our products despite compromising the superior quality of each SWR pipe makes us a partner of choice for several industrial and commercial projects throughout the country.

SWR Pipes & Fittings – Engineered for Efficiency by a Leading SWR Pipes & Fittings Manufacturer

We ensure that each of our SWR pipes and fittings products undergo stringent testing to ensure unparalleled strength and durability, adhering to the highest industry standards. At Utkarsh Pipes & Fittings, we are committed to offering products of exceptional performance and quality, establishing ourselves as a trusted SWR pipe manufacturer in India.With the many years of expertise and technical know-how, we take immense pride in being the most trusted SWR pipes and fittings manufacturer in India and around the world. We are able to consistently exceed client expectations due to our unwavering commitment to quality and our innovation-first strategy.

- Precision engineering ensures leak-proof joints, preventing water spillage

- Rigorous quality checks at six production stages ensure consistent reliability

- Compatible with various SWR pipe fittings for comprehensive plumbing solutions

- Versatile, ideal for a wide range of applications

- Self-extinguishing feature adds protection against combustion

-

44000

Plant Area

-

68000

Production Capacity

-

5000

Ready Stock

Product Specifications

Explore the detailed specifications of our SWR pipes fittings, ensuring top-grade performance, durability, and reliability with international standards for diverse applications. As a leading SWR pipe manufacturer in India, we ensure that all our products adhere to stringent quality parameters.

Read the technical details of our SWR pipe fittings, which highlight accurate dimensions, high-grade materials, and performance standards for dependable uses.

- Size range: Pipes - 75mm, 110mm, 160mm; Fittings - 75mm, 110mm, 160mm

- Standards:

IS: 13592 (Pipes) IS: 14735 (Fittings) - Fittings: 75mm

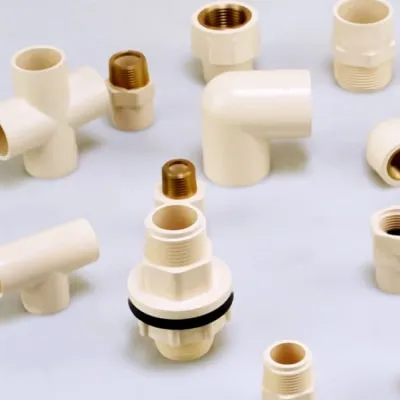

Coupler, Tee, Double Tee, Bend, 45° Bend, Y, Double Y, Clip, Vent Cowl, Reducer, WC Connector, Nahani Trap, Pass Over, Door Tee, Door Tee RH/RH, Double Tee Door, Plain Bend, Door Bend, Double Y with Door, Cleaning Pipe, End Cap, P-Trap, Door Cap. - Fittings: 110mm

Coupler, Tee, Double Tee, Bend, 45° Bend, Y, Double Y, Clip, Vent Cowl, P-Trap, S-Trap, Reducer, WC Connector, Nahani Trap, Pass Over, Door Tee, Door Tee RH/RH, Double Tee Door, Plain Bend, Door Bend, Double Y with Door, Cleaning Pipe, End Cap, Door Cap. - Fittings: 160mm

Coupler, Tee, Bend, 45° Bend, Y, Clip - Length:

3m & custom lengths

Our SWR pipes and fittings are manufactured to the highest standards possible, adhering to strict industry guidelines for dependability and quality.

- Quick & easy installation due to lightweight:

Installation is a breeze with our lightweight design, making setup quick and hassle-free. - UV-stabilised to ensure lifetime endurance:

UV-stabilised for superior durability, ensuring long-lasting performance even under harsh sunlight. - Leak Proof joints & maintenance-free systems:

Enjoy peace of mind with our leak-proof joints, offering a maintenance-free experience for years to come. - Specially compounded to withstand rugged outdoor installation:

Engineered for rugged outdoor use, our product is specially compounded to handle the toughest environments. - Chemical resistant (especially to most household chemicals), high flow rate with smooth & no scaling or depositions:

Resistant to most household chemicals, our system ensures a high flow rate with no scaling or deposits for smooth, efficient operation.

Explore our PVC SWR pipes and fittings' further characteristics,

which include important information on compatibility, performance

features for a range of applications, and ease of installation.

- All pipes & fittings in strict compliance with standards:

Guaranteed precision and reliability with SWR pipes and fittings that meet all industry standards. - Corrosion & rust-proof:

Built to resist corrosion and rust, ensuring lasting performance of our SWR pipe fittings even in the harshest conditions. - Designed for long durability & service:

Engineered for extended durability, providing dependable service life for years to come. - Self-extinguishing:

Safety-first design with self-extinguishing properties for enhanced fire protection. - Attractive steel grey colour:

Features a sleek steel grey finish for a modern and professional appearance.

| Types | Printing Colour | Sizes Available | As Per Standards |

|---|---|---|---|

| Type A | Blue | 75 mm, 110 mm and 160 mm | IS: 13592 |

| Type B | White | 75 mm to 160 mm | IS: 13592 |

Product Fittings

Explore the detailed specifications of our SWR pipes fittings, ensuring top-grade performance, durability, and reliability with international standards for diverse applications. As a leading SWR pipe manufacturer in India, we ensure that all our products adhere to stringent quality parameters.

Application Areas

Manufacturing Process

-

Raw Material Preparation

The raw materials and chemicals are fed into a high-speed mixer using an automatic system, following a pre-set recipe. Once the mixture reaches the designated temperature, it is transferred to a cooling chamber until it cools to a predefined temperature, and then the compound is sent to the extruder hopper.

-

Extruder Feeding

The cooled material is fed into the extruder through a hopper, utilising either a gravimetric or volumetric control system to ensure precise measurement.

-

Melting the Material

Inside the extruder barrel, the material is heated to the melting point of around 180°C. This process occurs under load (melt pressure) and with the help of friction in the twin-screw system.

-

Pipe Formation

The melted material is pushed through a die-head (also known as a spider) to form the shape of the pipe.

-

Calibration and Cooling

The newly formed pipe is calibrated to the correct size using a sizing system in a vacuum sizing tank, followed by cooling in a spray tank with water.

-

Cutting and Inspection

At the end of the production line, pipes are printed, cut to specified lengths, and socketed. Each pipe undergoes standard checks during online inspection and testing, and is then sent for further processing (threading and slotting) as per the intended use.

-

Final Quality Assurance

Final inspection by the Quality Assurance (QA) team ensures that all pipes meet quality standards before being categorised as finished goods. Finally, the pipes are dispatched according to delivery orders (DO).