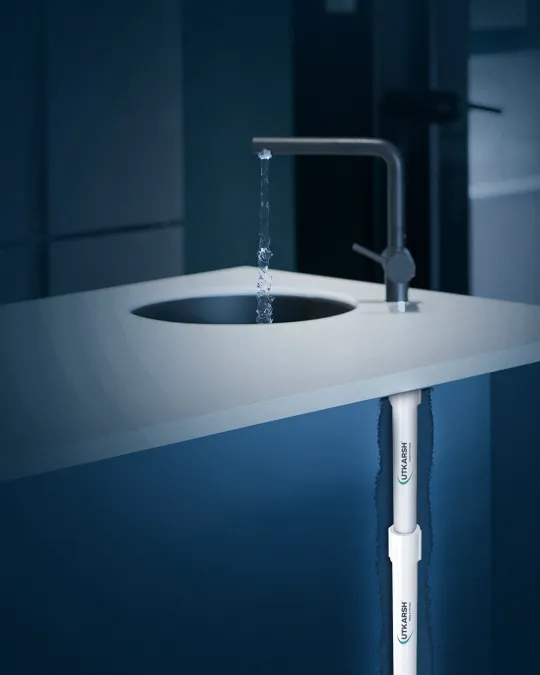

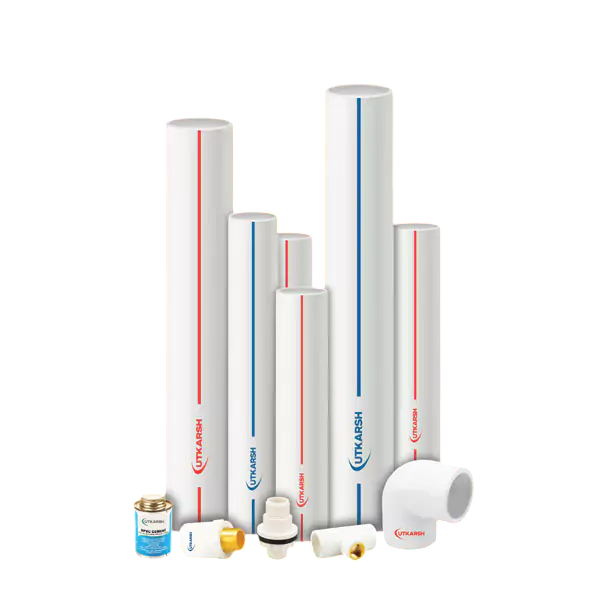

For decades, Utkarsh Pipes & Fittings has been a leading manufacturer and supplier of high-quality uPVC pipes. Our uFLO uPVC pipe & fittings are meticulously crafted from top-grade, lead-free materials, ensuring smooth, safe, and efficient cold water transportation.

Manufactured in-house at our state-of-the-art facilities, our products benefit from our deep technical expertise in plastic piping technology. We deliver pipes with unparalleled durability, performance assurance, and UV radiation resistance, catering to diverse industries and applications worldwide. This commitment underlines our position as the most trusted uPVC pipe manufacturers in India.

Explore our extensive uPVC pipe product portfolio and experience the reliability and innovation that define Utkarsh Pipes & Fittings. Whether in India or beyond, we’re committed to meeting your piping needs with excellence.

uFLO uPVC Pipes & Fittings – Innovation from a Trusted uPVC Pipe Manufacturer

Recognized as one of the prominent uPVC pipe fittings manufacturers, we engineer our uFLO pipe fittings with unplasticized polyvinyl chloride which exhibits excellent UV resistance. It's a true mark of our drive for superior manufacturing and continuous technological progress. These pipes and fittings boast easy installation, significant functionality advantages, and exceptional hygiene standards.Manufactured in-house at our state-of-the-art facilities, our products benefit from our deep technical expertise in plastic piping technology. We deliver pipes with unparalleled durability, performance assurance, and UV radiation resistance, catering to diverse industries and applications worldwide. This commitment underlines our position as the most trusted uPVC pipe manufacturers in India.

Explore our extensive uPVC pipe product portfolio and experience the reliability and innovation that define Utkarsh Pipes & Fittings. Whether in India or beyond, we’re committed to meeting your piping needs with excellence.

- Economical and highly suitable for water transportation & distribution.

- Lead-free assurance for drinking water hygiene and safety.

- Designed with the finest sourced raw materials.

- Highly durable, value-added plumbing solution.

-

44000

Plant Area

-

68000

Production Capacity

-

5000

Ready Stock

Product Specifications

Discover the precise specifications of our uFLO uPVC pipes and fittings, crafted to meet the highest standards for reliability, functionality and overall performance.

Get all the details about the technical specifications of our uFLO uPVC pipes and fittings, ensuring optimal performance and durability for various applications.

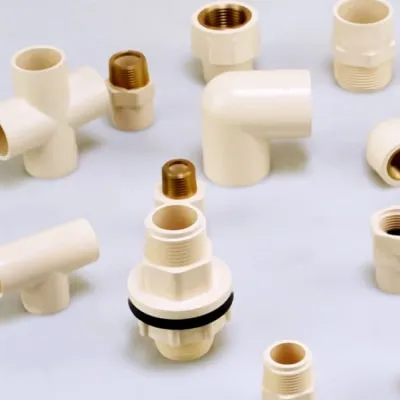

- uPVC pipes sizes: Push in Pipe Size of 20MM TO 50MM

- uPVC fittings sizes: Threaded and Push in Size of 20MM TO 50MM

- Pipes manufactured in adherence to ASTM D 1785 Schedule 40 & 80 standards

- Fittings manufactured in adherence to ASTM D 2467 Schedule 80 standards

- Crafted from UV-resistant materials, ensuring long-lasting durability

Explore the standard specifications of our uFLO uPVC pipes and fittings, meticulously crafted to meet industry standards for superior quality and performance consistency.

- Lead-Free Composition:

Our uFLO uPVC pipes and fittings are made from lead-free materials, ensuring they are safe for drinking water and compliant with stringent health standards for maximum safety. - Six-Stage Rigorous Testing:

Each pipe and fitting undergoes a thorough six-stage testing process, guaranteeing adherence to the highest quality standards and providing unmatched reliability and safety in every product. - Extensive Product Range:

We offer a comprehensive range of uPVC pipes and fittings, designed for various applications, from residential plumbing systems to complex industrial process lines, catering to diverse customer needs. - Hygienic and Safe for Drinking Water:

Our uPVC pipes are hygienically designed to prevent contamination, ensuring safe and clean water transport for both residential and commercial applications, making them ideal for potable water supply. - Optimum Flow Rates and No Clogging:

Our uFLO uPVC pipes feature a smooth interior surface that minimises friction, providing optimal flow rates and eliminating the risk of clogging for efficient water distribution.

View the additional specifications of our uFLO uPVC pipes and fittings, tailored to meet specific needs of diverse applications and ensure uniformly optimal performance.

- Lightweight; Easy to Install, Transport, and Handle:

Our uFLO uPVC pipes and fittings are lightweight, making them easy to transport and handle, which significantly simplifies installation and reduces labour costs for all types of projects. - Minimal Maintenance Requirements:

Designed for longevity and reliability, our uFLO uPVC pipes require minimal maintenance, providing a cost-effective solution with lower operational expenses over their lifespan, ensuring hassle-free usage. - Excellent Chemical and Corrosion Resistance:

Our uFLO uPVC pipes and fittings offer outstanding resistance to chemicals and corrosion, making them ideal for harsh environments and various industrial applications where durability is crucial. - A Wide Range of Pipes and Fittings:

We provide an extensive selection of uFLO uPVC pipes and fittings to cater to the specific needs of different applications, ensuring flexibility and compatibility with diverse plumbing systems. - Weather-Proof Resistance; No Scaling or Sedimentation:

Our uFLO uPVC pipes are engineered to withstand extreme weather conditions and prevent scaling or sedimentation, ensuring a consistent and reliable water flow without blockages or degradation.

| Sizes Available | As Per Standards | |

|---|---|---|

| uPVC Pipes | Push in Pipe Size of 20MM TO 50MM | ASTM D 1785 Schedule 40 & 80 |

| uPVC Fittings | Threaded and Push in Size of 20MM TO 50MM | ASTM D 2467 Schedule 80 |

| Sizes Available | As Per Standards | |

|---|---|---|

| uPVC Pipes | Push in Pipe Size of 20MM TO 50MM | ASTM D 1785 Schedule 40 & 80 |

| uPVC Fittings | Threaded and Push in Size of 20MM TO 50MM | ASTM D 2467 Schedule 80 |

Product Fittings

Explore our range of uFLO uPVC pipe fittings designed for seamless integration and optimal performance in various plumbing applications. As India’s one of the trusted uPVC pipe fittings manufacturers, we make sure that all our products are rigorously tested and are of optimal quality.

Application Areas

Manufacturing Process

We consistently adhere to a meticulous process for our range of uPVC pipes and fittings, ensuring quality from raw material selection to final inspection and packaging, which defines us as a dedicated uPVC pipe manufacturer.

-

Raw Material Preparation

Raw materials and chemicals are automatically fed into a high-speed mixer using the SCADA system, following a pre-set recipe. Once the mixture reaches the required temperature, the compounded material is transferred to a cooling chamber to reach a predefined temperature, then sent to the extruder hopper.

-

Material Feeding

The material is fed into the extruder through a hopper, regulated by a gravimetric or volumetric control system to ensure accurate proportions.

-

Heating and Melting

Inside the extruder barrel, the material is heated to its melting point at around 180°C. The twin-screw system applies pressure and friction to ensure consistent melting.

-

Pipe Formation

The melted material is pushed through a die-head, also known as a spider, where it is shaped into a pipe.

-

Calibration and Cooling

The pipe is calibrated to the correct size using a vacuum sizing tank and cooled down in a spray tank with water.

-

Cutting and Socketing

At the end of the production line, the pipes are printed, cut into specific lengths, and socketed based on their intended use.

-

Inspection and Dispatch

The pipes undergo thorough online inspection and testing during production. After production, the pipes are checked again by Quality Assurance (QA) before being moved to the finished goods section for dispatch as per the delivery order (DO).