Related Blogs

Explore more with our related blogs on our products, manufacturing processes, solutions and more.

What are PVC Pipes? Uses, Benefits, and Applications Explained

Sep 19, 2025

In the plumbing sector, Polyvinyl Chloride (PVC) pipes are one of the widely used pipeline materials across domestic, agrarian, and industrial sectors. It's well-known for affordability, strength, and versatility, PVC pipes have truly converted ultramodern plumbing and structure development. Whether the water force is for irrigation or a large-scale artificial design, the advantages of PVC pipes make them a top choice for masterminds, contractors, and homeowners alike.

At Utkarsh Pipes, a trusted PVC pipe manufacturer, we deliver high-quality PVC pipes results designed to meet different design conditions with long-continuing performance.

What are PVC Pipes made of?

PVC pipes are made of polyvinyl chloride, a strong and lightweight thermoplastic material. This material undergoes extrusion processes to form pipes with different dimensions and pressures. The features like corrosion resistance and chemical resistance outperform traditional materials like metal and concrete in many applications.

Common Types of PVC Pipes and Their Uses

Different types of PVC pipes are designed to cater to specific applications. Some of the common categories include:

| Type of Pipe | Features | Uses | Technical Specifications |

|---|---|---|---|

| uPVC Pipes | Rigid and lightweight, corrosion & chemical resistant, cost-effective | Cold water plumbing, agricultural irrigation, sewerage & drainage | Pressure rating: 2.5 to 16 kg/cm²; Diameter: 20 mm to 400 mm; Standards: IS:4985 |

| CPVC Pipes | Withstands high temperatures, resistant to scaling & corrosion, smooth inner surface | Hot & cold water supply, industrial fluid handling, fire sprinkler systems | Temp. resistance: up to 93°C; Diameter: 15 mm to 150 mm; Standards: IS:15778 |

| PVC Casing Pipes | Specially designed for borewells, durable, resistant to soil & water conditions | Borewell casings, groundwater extraction, submersible pump installations | Diameter: 40 mm to 250 mm; As per IS:12818; Ribbed & plain casing options |

| SWR Pipes | Strong, leak-proof, UV-stabilized, resistant to household/industrial waste & rainwater | Soil, waste & rainwater drainage in residential, commercial & industrial use | Diameter: 75 mm to 160 mm; Standards: IS:13592; Available in Push-fit & Solvent cement joints |

| Column Riser Pipes | High tensile strength, leak-proof joints, designed for heavy vertical loads | Submersible pump risers in deep borewells | Diameter: 25 mm to 150 mm; Pressure rating: up to 25 kg/cm²; Standards: IS:14151 |

| Agriculture Pressure Pipes | Designed for high-pressure water flow, UV-stabilized, weather & corrosion resistant | Irrigation, drip & sprinkler systems, farm water supply | Diameter: 20 mm to 400 mm; Pressure rating: 2.5 to 16 kg/cm²; As per IS:4985 |

| Garden Pipes | Flexible, lightweight, easy to handle, resistant to kinking & abrasion | Household gardening, car washing, light irrigation, cleaning | Diameter: 0.5 inch to 1.5 inch; Available in 30m/50m/100m coils |

| HDPE Pipes | Flexible, impact-resistant, high chemical & corrosion resistance | Industrial fluid transport, irrigation, sewage, cable ducting | Diameter: 20 mm to 1000 mm; Pressure rating: PN 2.5 to PN 20; Standards: IS:4984 |

| PLB HDPE Ducts | Permanently lubricated inner surface, UV-resistant, high crush resistance | Optical fiber cable protection, telecom & data cable management | Diameter: 32 mm to 110 mm; Conforms to TEC & BSNL standards; Colors with stripes for ID |

Advantages of PVC Pipes

The advantages of PVC pipes extended beyond just cost savings. Their unique properties make them the most dependable and versatile piping solution available today.- Lightweight and Easy Installation: PVC pipes are much lighter compared to traditional materials like steel or iron. This lightweight material is easy to transport, handle, and install in remote areas. Moreover, this indirectly cuts the labour cost and no such heavy tools are required for installation.

- Durability: One of the biggest advantages of PVC pipe is its durability. PVC has a resistance power towards corrosion and scaling. This long-term service ensures uninterrupted services in any sector, like industry and residential.

- Chemical Resistance: Chemical Resistance cPVC pipes are specifically designed for handling tough surroundings with superior chemical resistance, since they're largely dependable for the environmentally aggressive chemicals, fertilisers, or artificial fluids. This ensures long-term continuity and a safe pipeline system in chemical processing and wastewater operation.

- Low Maintenance: The smooth inner filling face of the PVC minimizes the blockage or deposits, which reduces the need for frequent changes and repairs. Their robust design prevents cracks, leaks, or breakdown. Still, this makes a dependable choice for multiple sectors.

- Sustainability and Eco-Friendly: When it comes to recyclable accoutrements, PVC is the first choice. This product's lifetime is longer compared to other piping materials. Choosing PVC support offers an eco-conscious and long-term solution for water management and infrastructure projects.

Application of PVC Pipes

Choosing PVC support offers long-lasting performance, efficiency, and safety across different working sectors. Looking at the uPVC pipes, they're ideal for cold water, drainage, and general operations. cPVC is designed for high-temperature and chemical resistance purposes. Alternatively, PVC casing pipes are used only for borewell and groundwater systems.’

To gain a better understanding, a detailed comparison is presented with the types of PVC suitable for each sector and specific applications.

| Sector | uPVC Pipes | CPVC Pipes | PVC Casing Pipes | SWR Pipes | Column Riser Pipes | Agriculture Pressure Pipes | Garden Pipes | HDPE Pipes | PLB HDPE Ducts |

|---|---|---|---|---|---|---|---|---|---|

| Plumbing & Sewage | Cold water plumbing, sewage, and rainwater harvesting. Lightweight & durable. | Hot & cold water in bathrooms, kitchens, and sprinkler systems. | Rarely used in homes, only in a small borewell supply. | Drainage and sewerage systems in residential and commercial buildings | Limited in plumbing, occasionally used for residential borewell lifting. | Not typical for plumbing. | Commonly used for household gardening & cleaning purposes. | Used in some modern homes for underground plumbing and sewage. | Rarely applied in plumbing; used for telecom in smart homes. |

| Agriculture | Farm irrigation, water distribution, and drainage networks. | Limited role, occasionally in hot water agricultural setups. | Borewell and tubewell casing for safe groundwater. | Efficient disposal of wastewater, soil, and rainwater | Widely used in agriculture borewells for submersible pumps. | Ideal for irrigation, drip & sprinkler systems under high pressure. | Suitable for spraying, washing, and light irrigation. | Widely used in irrigation, drainage, and sprinkler systems. | Limited use in automation setups with fiber-based sensors in agriculture. |

| Industrial | Drainage, cable ducting, and fluid transport. | Transport of hot water, corrosive fluids, and chemicals in factories. | Used in deep well casings for industrial water supply. | Used in industries for non-pressure waste lines | Applied in industrial borewells requiring heavy-duty strength. | Sometimes used in water circulation systems in industries. | Light-duty industrial cleaning & water supply. | Transport of chemicals, slurries, and high-pressure fluids. | Extensively used in telecom & data cable housing for industrial connectivity. |

| Boring System | Limited use, except for small bore casings in residential areas. | Rarely used in boring applications. | Designed for borewell and tubewell casing to ensure safe groundwater extraction. | Core application: submersible pump risers for deep borewells. | Occasionally used in boring-related water distribution setups. | Minimal role in boring; sometimes for washing bore points. | Used for supporting borewell systems requiring pressure resistance. | Not used directly in boring, but supports telecom/data networks in bore areas. |

Why Choose Utkarsh PVC Pipe Manufacturer

Utkarsh Pipes has earned its reputation as one of the trusted and reliable PVC pipes manufacturers, delivering excellent quality, from designs to installation support. These are the standpoints features to associate with Utkarsh Pipes:

Complete Range of PVC Solutions

Utkarsh Pipes offers a one-stop solution for all kinds of piping solutions for every sector, such as residential, agriculture, industrial, or infrastructure requirements. Whether it's a hot water supply or a borewell application, our piping solutions are customised to maximise efficiency.

High-Quality and Manufacturing Standard

Utkarsh Pipes uses premium-quality raw material and a global standard, ensuring long-lasting performance and reliability.

Industry Expert and Networking

With 5 decades of experience and trusted by leading developers, contractors, and businesses across India. Over the years, we have built a strong industry network and partnership that allows us to stay ahead with remarkable projects.

Strength and Durability

Our pipes are designed to withstand any pressure, temperature, or exposure to chemicals. Utkarsh PVC pipes have ensured they produce a seamless product in urban areas for decades.

Commitment and Sustainability

We believe in a sustainable future by optimising recyclable, eco-friendly PVC pipes. We support Sustainable Development Goals, focusing on reducing the carbon footprint.

Wrapping Up

PVC pipes have transformed the plumbing system. The features of PVC make it a necessary result for domestic, marketable, and agrarian operations. From safe drinking to sewage networks, all the PVC pipeline networks are vast and vital. Still, the true value of PVC lies not in the accoutrements but in the quality of manufacturing and determination behind it. This is where Utkarsh Pipes stands out with its complete range of uPVC, CPVC, PVC containing pipe, the state-of-the-art installation, and strict quality control. Utkarsh Pipes ensures that every product meets the loftiest standard of safety, performance, and sustainability.

Contact Utkarsh Pipes today to find the right PVC solution for your project.

What to Consider When Comparing Water Tank Manufacturers?

Sep 17, 2025

Selecting the right tank for your requirement, such as household, commercial complexes, and industrial uses. Selecting the right water storage tank as well as manufacturer plays a significant role in ensuring safety, durability, and hygienic water for everyday use. A plastic water tank is a reliable and a safe choice for drinking purposes as well. As there are a number of manufacturers in the market, looking for a suitable company might be overwhelming. Knowing what to look for can ease the decision-making process and lead to a confident purchase. The most focused factor while choosing the best water tank company is product quality. A water tank should meet the local and global safety standards. When assessing different water storehouse tank manufacturers, check if they maintain the standard with quality norms for water tanks, such as food-grade plastic instruments, UV resistance, and continuity against harsh rainfall. Tanks made with poor-quality accoutrements can compromise water safety and lead to advanced conservation costs. The quality transparency is the foremost feature a company should be bound by. In the case of Utkarsh Pipes and Fittings, they follow the criteria Special Six- Shoulder Design for Superior Compressive Strength. This design enhances compressive strength, allowing the tank to repel heavy loads and pressure without damage. 10% Extra Storage Leading overhead water tank manufacturers in India now give tanks with 10% redundant storage capacity, offering better value for cost and added value for customers. Multi-Ribbed Design for long-lasting strength, the addition of a multi-ribbed structure improves durability, ensuring the tank lasts longer under varying conditions. 10 years warranty, along with a bond, is a sign of trust and product confidence. Utkarsh Pipes, as the best water tank manufacturers, offer extended guarantees, reflecting their confidence and assurance. A dependable water tank manufacturing company should offer a wide product range, covering household tanks, overhead storehouses, and industrial-grade tanks. The flexibility of sizes, colors, and designs helps guests find a tank suited tank for their specific needs. The most popular choice in the moment comes from plastic water tank manufacturers, as these tanks are featherlight, corrosion-resistant, and long-lasting. Look out for those manufacturers who use rotational molding or advanced blow molding methods for invariant consistency and strength. Similar technology ensures that tanks don't crack or blunder fluently, conserving water quality for times. Another critical consideration is continuity. The best water tank company will confidently offer a long-term bond, reflecting the trust they place in their own products. Compare the bond terms and ensure that after-sales service is available in your region. An authorised water tank manufacturing company won't only deliver quality but also give ongoing support. Client feedback is a strong index of trustworthiness. Research online feedback and reviews when shortlisting water storage tank manufacturers. Reputed companies constantly maintain product quality, ensure timely delivery, and give professional service. This becomes especially important if you're searching online for a water tank company, as genuine client satisfaction shall recommend original credibility. Utkarsh Pipes and Fittings has built a strong reputation backed by fifty years of experience and innovation. Utkarsh understands the evolving needs of households, businesses, and industries with over five decades of serving water management industry. As a leading water storage tank manufacturer, Utkarsh pipes and fittings ensure designs are manufactured with advanced molding technology. Utkarsh Pipes and Fittings sets a benchmark for the quality standards for water tanks, offering UV resistance, Food-grade quality, and a long-lasting, durable solution. Utkarsh Pipes and Fittings is recognized in the local and global markets for water storage tanks. Comparing water tank manufacturers goes beyond price; the priority is about safety, durability, and long-term performance. Additionally, warranty and brand reputation help you to make an informed decision. Credibility begins with a reliable, durable, and high-performance solution. Choose one backed by trust and performance, like Ukarsh Pipes and Fittings proves to be a leading name in the market among the top manufacturing companies in India. Make a smart choice, go for Utkarsh Pipes and Fittings.Quality Norms for Water Tanks

Diverse Range of Products

Raw Material and Technology

Durability and Warranty

Brand Reputation and Reviews

Why Utkarsh Pipes and Fittings Standouts?

Final Thoughts

How Do SWR Pipe Manufacturers Address Urban Wastewater Challenges?

Aug 27, 2025

In an urban area, wastewater management is an accelerating issue. Citizens need to expand their waste solution in both a sustainable and efficient way. In this context SRW pipes manufacturer plays an essential role in addressing the urban wastewater challenges by crafting a robust and durable system, eco-friendly and can withstand all the hazardous chemicals and substances flown throughout. Urban wastewater consists of both sewage and stormwater waste solutions, which can lead to flooding, waterlogging, and public health hazards. The increasing construction and infrastructure growth often shows immense pressure on drainage networks; as a result, pipes face frequent breakdown, contamination, and blockage. This situation creates a requirement for the replacement or repair of SWR pipes causes a financial burden to the owners. Unlike traditional drainage solutions, modern SWR urban solutions are engineered to manage a large volume of wastewater seamlessly while ensuring minimum maintenance and maximum durability. A leading SWR pipes manufacturer uses high-quality PVC compound with features resistance to corrosion and chemicals. It ensures long-lasting performance in demanding situations where pipes are constantly exposed to waste flow. The smooth inner surface of SWR pipes prevents from clogging and deposition of substances. This makes SWR pipes for urban drainage minimize the blockage and reduce the risk of overflow during heavy rains. Flooding is a common issue during the monsoon season. To fight against SWR pipe manufacturers, design pipes featuring leakproof technology, flexible fittings that can efficiently channelize the storm water solution from both residential and commercial areas. It is considered an ideal solution because of its easy joining techniques, which makes it easy in the installation time as well as cost, considering essential factors for fast-developing urban regions. An eco-conscious productivity heavily reduces carbon emissions. It not only counts as an efficient wastewater management solution but also ensures urban development aligns with environmental sustainability. Durability: Resistance against weathering, rust, and decay Hygiene: Protective coverage from leakage and contamination Cost-efficiency: Long lifespan with less maintenance cost Scalability: Suitable for both small residential buildings and large commercial complexes Utkarsh Pipes and Fittings has more than fifty years of experience in the pipes and fittings niche. Our products are backed by advanced research and development, strict quality checks, and compliance with international and national standards certified by ISO, adhering to IS:1359 (Pipes) and IS:14735 (Fittings), ensuring full compliance for wastewater solutions. Utkarsh Pipes and Fittings delivers durability, hygienic, and cost-effective piping solutions across the country. It represents a benchmark of credibility and innovation in sustainable wastewater solutions. Urban wastewater management needs a smart, sustainable, and lasting solutions approach. Integrating advanced technology and eco-conscious design solutions for the SWR pipe manufacturer contributes significantly to solving maximum urban challenges. From ensuring stormwater waste solution to supporting reliable SWR for urban drainage. SRW Pipes remain the backbone of sustainable city infrastructure. At Utkarsh Pipes, we take pride in partnering with futuristic projects and providing a cutting-edge solution to mitigate the urbanisation demand. We are committed to quality and the trust our customer shows us.Understanding the Urban Wastewater Challenges

How Manufacturing Creates an Effective Solutions

Advanced Material Technology

Efficient Design for Urban Drainage

Adaptability to Stormwater Waste Solution

Easy Installation and Low Maintenance

Eco-Friendly and Sustainable Practices

Why SWR Pipes are the Backbone of Urban Waste Solutions?

Why Choose Utkarsh Pipes for SWR Waste Solutions?

Wrapping Up

What Are the Maintenance Tips for Long-Lasting Water Storage Tanks?

Aug 27, 2025

Similar to how you maintain your physical health each day, your water storage system requires regular attention to ensure it stores clean, safe water. Water storage tanks are used in any household or commercial property and are critical to providing a constant water supply for drinking, daily routines, and tasks. However, it is not enough to assume that by simply installing a tank, you can forget it; regular maintenance is essential to drinking water quality and the longer service life of the tank. This blog will provide a summary of water tank maintenance insights. You can take these tips and apply them to any water tank, whether for household, office, commercial, or large industrial use. Without regular inspections, a tank can rapidly build up dirt, algae, bacteria, and other microbial organisms, all of which reduce the quality of your water and the lifespan of the water tank. So, taking a handful of maintenance tips from professionals will help you have a more effective water storage system for your daily use. Only buying a premium quality water tank or frequently replacing the tank is not a solution. Maintaining a water storage tank is about ensuring the safety and quality of the water you consume every day. Neglecting the maintenance can create several issues for the tank. However, this can lead to several issues, like health issues, such as diarrhea, cholera, or sometimes skin infections. Lack of proper cleaning water tank allows microbial organisms like algae or bacteria. You may also notice an unpleasant change, like foul smell or a strange taste, which is caused by excessive microbial growth. Beyond this hygiene concern, tanks get damaged by corrosion, leaks, or cracks. If you don’t take the small concern seriously, it might not take time to become an issue for you and your family. Above all, the maintenance practice of cleansing the water tank at regular intervals is the key to preventing any hazards. Here is the step-by-step process: Drain out the water completely, empty the tank ensure no water remains inside. Scrub the inner surface of the tank, using mild detergent or any recommended chemical to remove dirt, microbial compounds from the tank. Wash out the tank several times to ensure no soap or chemical residue remains inside. For additional safety, apply a safety disinfectant such as a chloride solution to kill harmful bacteria or microbes. Dry up the tank naturally before refilling with fresh water for use. Regular Inspection of the tank: Every three months, inspect the tank for cracks, leaks, or discoloration. Early prevention can prevent major damage and costly repairs. Cover the tank with a sealed lid to protect against insects, dust, and external pollutants. Ensure ventilation pipes are properly screened to function well to prevent leakage and water wastage. UV rays of the sun can expose algae and other microbial growth inside. Place the water storage in a shaded area or choose a UV-stabilized tank. Check the inlets, outlets, and valves to prevent leakage or wear. Timely replacement of the faulty parts keeps the tank from efficiently functioning. Choose a high-quality tank that is 100% food-grade virgin, UV stabilized, and multi-layer protected with hygiene, strength, and durability. Reduces the risk of waterborne disease Becomes cost-efficient in terms of repair and replacement Extend the lifespan of your tank Ensure safe and clear water for everyday use When it comes to ensuring safe, clean, and long-lasting storage, choosing the right water tank is the initial stage to make a difference. Not every tank is reliable; it is preferred and safer to invest in a quality product. This is where Utkarsh Pipes stands out as a trusted choice across both household and commercial properties. Utkarsh Pipes and Fittings are backed by more than 50 years of industrial experience. Each tank manufactures 100% food-grade virgin LLDPE to certify that the water consumed is trusted for drinking, cooking, and sanitation remains hygienic and safe. Utkarsh Pipes water storage tanks are UV stabilised to withstand the harsh Indian climate. Moreover, Utkarsh Pipes offers multiple sizes, starting from small household to large commercial uses. Their range of products makes Utkarsh Pipes a one-stop solution for all your needs. Your water storage tank is not just a container; it is the gatekeeper of your family to keep every drop of water clean and crystal clear. It acts as a silent guardian who takes care of your health and hygiene. Regular inspections, timely cleaning, and consistent maintenance are the essential steps to ensure a better experience with your water connectivity. Whether it’s your home, office, or industries, Utkarsh Pipes and Fittings ensure water is stored most hygienically and securely as possible Contact Utkarsh Pipes to explore the wide range of products with premium quality for your well-being.Why is Water Storage Tank Maintenance Important?

Process of Cleansing Tanks

Effective Maintenance Tips for Water Storage Tanks

Benefits of Tank Maintenance

Why Choose Utkarsh Water Storage Tank?

Wrapping Up

What Materials Are Commonly Used in Riser Pipes for Deep Wells?

Aug 26, 2025

Riser pipes play a crucial role in lifting water from underground aquifers to the surface. A deep well riser pipe material directly affects the durability and cost-effectiveness of the entire water supply system. Common materials include uPVC compound and heavy-duty sealing rings made of industrial-grade rubber, which guarantee long-lasting performance. They also absorb pump vibrations, extend the life of the system, and ensure a hassle-free water supply. A riser pipe acts as a vertical column, connecting the borewell pump to the water delivery point. In a deep well application, these pipes are subjected to high water pressure, varying load conditions, and chemical reactions with groundwater. Choosing the correct material ensures safety, reliability, and longevity of the system. The choice of deep well riser pipe material is a technically and economically wise investment idea. Since riser pipe is used to carry water under high pressure from hundreds of feet below. Unlike other pipes may corrode, collapse, or break under stress, leading to pump failure, water contamination, or downtime. Leak-proof performance with zero water loss Resistance to corrosion in aggressive groundwater conditions Reduces the maintenance cost Consistent and safe water supply for agriculture, industry, and domestic use Utkarsh Pipes manufactures riser column pipe exclusively from superior uPVC material, a choice backed by experience and performance in the field. This is because uPVC has proven to be the most efficient, durable, and cost-effective option for deep well applications. Resist corrosion in every aggressive condition Lightweight pipes are easy to transport and install Long service life with minimal maintenance Cost-effective product compared to any metallic pipe Provide smooth water flow due to the advanced joining system High load-bearing capacity, suitable for a submersible pump Sustainable lifespan with low maintenance Protect against leakage, scaling, and bacterial contamination Worthwhile investment for farmers, industries With over 5 decades of industrial experience, Utkarsh Pipes has played a significantly an ideal role in shaping water infrastructure. Our product lasts long and reflects a deep understanding of the challenge faced by consumers. Utkarsh Pipes and Fittings is widely recognised for its engineering excellence and innovative power. Its superior uPVC compound is designed to handle high torque and also suitable industrial-grade sealing rings that can also absorb the vibration of the pump, extend the pipe life, and ensure leak-proof use. As an ISO certified company, Utkarsh Pipes sets a global standard in the Indian market with its eye-catching product quality. Moreover, our product has been popularly used in every business sector, like agriculture, industry, and construction projects. Utkarsh Pipes built its reputation on the foundation of consistency, transparency, and reliability. Customers trust our brand not only for product performance, they believe in one- time investment with no further miscellaneous costs on repair or replacement. The choice of deep well materials determines the efficiency of extracting water from the well. Unlike traditional steel pipe, uPVC riser pipe deep well solution has offered more smarter alternatives in terms of cost-efficiency and hassle-free performance. Secure every drop with Utkarsh uPVC riser pipe, built for performance, trusted for life.Introduction to Riser Pipes

Importance of Choosing the Right Pipe Material

A High-Quality uPVC column pipe ensures:

Common Materials Used in Riser Pipe for Deep Wells

Features of Column Riser Pipes are:

Riser Pipe Benefits in Deep Well

Multiple benefits of riser pipe:

Why Utkarsh Pipes for Deep Well Riser Pipe Materials?

Conclusion

What Is the Ideal Length and Thickness for a Garden Pipe?

Aug 21, 2025

Homeowners and professional gardeners often face issues with gardening products like pipes that kink, burst under pressure, or don’t reach the required length. Choosing the right garden pipe size is essential that solve all these problems, making it effortless. Read on to learn how to select the ideal garden pipe length and thickness for your needs. The length usually ranges between 15mm to 25mm. Generally, a garden pipe’s size refers to the diameter and thickness that together determine water flow and durability. It is available in different variants, such as plastic and rubber. While smaller diameter pipes are ideal for home gardens, and larger sizes are suitable for heavy-duty uses from public gardens to industrial uses for cleaning. A garden pipe is also known as garden hose pipe. This is a versatile tool for watering plants, cleaning, or other outdoor tasks. Generally, it comes with a nozzle or sprayer to control the flow of water. Utkarsh Pipes and fittings are specially designed garden pipes keeping health and safety in mind, free from harmful chemicals, RoHS-compliant, phthalate-free, and non-carcinogenic, making them environmentally conscious and safe for home and business. Garden pipes are versatile tools that go beyond just watering plants. With the right garden pipe size and durable material, they can serve multiple purposes in the home, commercial, and industrial. These are some most commonly used: Watering plants in home garden and lawns Cleaning outdoor areas, patios, and vehicles Small-scale agricultural irrigation Supplying water for landscaping projects Paired with gardening tools and accessories Keep this checklist in mind: Measure the area that needs to be covered for watering Checking the diameter that provides a suitable water flow (Expert’s Advice: ½ inch for small gardens, ¾ inch for large spaces) Choose a thicker wall for longevity and durability Check for certified UV-resistant pipe Choosing the best garden pipe size is key and essential for durability, proper water flow, and hassle-free gardening. At Utkarsh Pipes and Fittings, we go beyond just supplying pipes, we deliver high-quality gardening products with a wide range and designs to meet both the household and professional needs. When it comes to choosing a trusted garden pipe manufacturer, Utkarsh Pipes and Fittings stand out with their innovation, safety, and reliability across India. To make your gardening experience smoother, easier, and efficient, choose Utkarsh Pipes today. The standard garden pipe size is ½ inch in diameter, regularly used for home gardens. If more water flow is required diameter of ¾ or 1 inch ensures better flow with high pressure required for other outdoor use. A small irrigation setup needs ¾ ¾-inch garden water pipe, which commonly delivers good water volume. Large agricultural irrigation systems require 1-inch or PVC pipes. Measure the total distance to be covered and the water pressure available in your tap. Small garden works well with ½ inch, and large lawns may need ¾ inch or 1 inch pipes No, it is designed only for cold and room temperature water. Special dedicated pipes are there for the temperature control pipe.What is the Ideal Length of a Garden Pipe?

What are the special features added to a garden pipe?

Key Benefits of Choosing the Right Garden Pipe Size

Common Application of Garden Water Pipe

How to Choose the Right Gardening Pipe Size

Conclusion

FAQs

Q1. What is the standard size of a garden pipe?

Q2. What size pipe is used for garden irrigation?

Q3. How to calculate the right pipe size?

Q4. Can a garden pipe handle hot water?

What to Look for in Pipe and Fittings Suppliers: A Contractor’s Guide

Aug 21, 2025

Every construction project is a race against time, quality, and budget. Only opting for a suitable supplier for the material is not enough; there are countless construction pipe suppliers in the market. Knowing how to choose the right partner for your project? Also, ensuring durability, timely delivery, and reliability of the material. This guide outsketch the significant factors a contractor should evaluate while choosing a supplier. Along with that, this guide shall evaluate why Utkarsh Pipes and Fittings is considered the best pipe supplier for contractors across India. A contractor might demand pipes and fittings that last for decades. Utkarsh Pipes ensures every product passes through a strict quality check, making it a trusted supplier in the construction field. For product reliability, the supplier should provide: ISI and ISO- certified products Leak-proof fittings Corrosion and pressure resistance A large-scale construction needs a supplier who can deliver a bulk of product without compromising delivery time, quality, and sustainability. Utkarsh Pipe has the capacity to deliver bulk production across India because: Having a robust production capacity Maintain adequate stock levels Ability to fulfill high-volume requirements This is one of the important factors to check upon, as an inaccurate time of delivery can disturb the whole workflow process, mainly leading to idle labour, miscellaneous costs, and missing deadlines. Therefore, before selecting a supplier, ensure the following key points: Wide distribution coverage Reliable logistic support Time-bound delivery commitments Make a one-stop destination for all kinds of requirements of pipes juggling to different vendors only leads to wastage of time and money. Utkarsh Pipe offers a complete range of pipes and fittings under one roof. Their piping product such as PVC, CPVC, UPVC, and HDPE pipes. Suppliers not only sell products, but they also guide contractors throughout the finishing process. Look for the supplier who has: Dedicated technical teams On-site support if required Transparent warranty and service team Utkarsh Pipes provides end-to-end solutions from product selection to after-sales support, to guide you in the best way possible. Fair Pricing and Value As per the expert’s advice, low-priced products are temporarily attractive, but in the long term, consumer needs to bear more cost on repair and replacement. Therefore, as a professional supplier should balance pricing with uncompromised quality. Certified Quality with a global standard Complete range of Pipes and fittings products Proven capacity for bulk orders Delivers product across India Provide technical expertise and strong customer support In the construction industry, piping and fittings are more than just a material; it's the backbone of any infrastructure. Henceforth, selecting the right pipe supplier is not just a role of procurement decision, it's a long-term investment and reputation of a contractor.Key Factors Contractor Must Check in Pipes and Fittings Suppliers

Product Reliability:

Bulk Supply Capacity:

On-Time Delivery:

Comprehensive Product Range:

Technical Guidance and After-Sales Support

Why Contractors Prefer Utkarsh Pipes and Fittings

Wrapping Up

A truly dependable supplier offers products that withstand every environmental challenge and pressure, ensuring durability, safety, and long-term performance for any construction project. So if you are looking for a reliable Pipes and fittings supplier, Utkarsh Pipes is your go-to choice. With Utkarsh Pipes by your side, every project stands strong and complete with confidence.

How uPVC Pipes Improve Plumbing Efficiency and Longevity

Jul 25, 2025

Among the most trusted and widely adopted solutions in modern plumbing systems is uPVC pipe. Designed to deliver long-term performance with minimal maintenance. These pipes are rapidly becoming the go-to choice both in residential and commercial projects. Whether you are a homeowner upgrading your plumbing infrastructure or a contractor seeking cost-effective and reliable materials, understanding how uPVC pipes improve plumbing efficiency and longevity can help you to make a smarter investment. Feature uPVC Pipes GI Pipes Copper Pipes Corrosion Resistance Excellent Prone to rusting Good Weight Lightweight Heavy Moderate Water Quality No taste or odor May affect taste and clarity Safe Installation Easy solvent-welded joints Requires threading and welding Soldering required Cost Efficiency Very cost-effective Expensive installation and maintenance High material and installation cost Maintenance Very low High (leaks, corrosion, scaling) Low Temperature Resistance Up to 60°C (ideal for cold water systems) Up to 100°C Excellent for hot water Longevity 40+ years 10–15 years 15+ years Eco-Friendliness 100% Recyclable Not recyclable Recyclable Ideal Use Residential plumbing, potable water and irrigation Industrial plumbing only Premium residential plumbing Long-Lasting Corrosion Resistance: uPVC pipes are built to withstand harsh environmental conditions. These pipes are non-reactive in nature ensure resistance against moisture, chemical exposure and aggressive water quality. Smooth Internal Surface for Optimal Flow: The inner surface of uPVC pipes is extremely smooth which reduces friction during water flow. As a result steady pressure with high efficiency in system. Thermal and Electric Insulation: The lower conductivity uPVC pipes help minimize heat loss in cold water systems. Additionally, a non-conductive material adds a layer of electric safety especially benefits to underground and high moisture installation. Lightweight and quick Installation: The lightweight design of uPVC plumbing pipes with simple and efficient installation and transportation. Installation can be completed faster with fewer tools and less manpower, which is especially valuable in large-scale or time-sensitive projects Low-Cost Maintanances and Long lasting Durability: Once installed the uPVC pipes require minimum maintenance. Their resistance to scaling, pitting and microbial growth greatly reduced the threads for clogging or leakage, resulting in long-term operational savings and worry free performance. At Utkarsh Pipes and Fittings we understand the importance of delivering reliable and sustainable piping system solution. As a leading uPVC pipe manufacturing company, we engineer ed with precision, made high grade raw material with rigorous taste and quality monitoring protocols. Working on diverse range like high-rises apartment, villas, or public infrastructure, Utkarsh Pipes craft a specialised pipes that meet the diverse demands of modern plumbing system. Our pipes are IS certified both domestic and international standards. Choosing uPVC plumbing from Utkarsh Pipes is a one-time solution while balancing durability as well as cost-effectiveness. From fast installation to minimal maintenance with excellent longevity, uPVC pipe installation can significantly improve the overall performance of plumbing systemsSmart Comparison Table: Why uPVC Outperforms Traditional Plumbing Materials

Key Benefits of uPVC Pipes in Plumbing Systems

Why Utkarsh uPVC Pipes are a Trusted Choice

Wrapping Up

Choose a trusted uPVC pipes manufacturer like Utkarsh Pipes and Fittings that perfectly blends innovation and reliability in every pipe.

What Testing Parameters Define a Trusted SWR Pipe Manufacturer?

Jul 24, 2025

Building an efficient drainage and waste disposal system requires high-performance SWR (Soil, Waste, and Rainwater) pipes. The quality of these components can significantly impact the durability and reliability of plumbing infrastructure. A trusted SWR pipes manufacturer stands out through rigorous testing procedures, strict quality control measures, and adherence to standards. This article outlines the key testing parameters that differentiate a reliable manufacturer, guiding professionals and buyers to help with the leak-free installation. SWR pipes and fittings are engineered for non-pressure applications, especially in drainage systems in houses, commercial, and industrial structures. SWR fittings are basic components like bends, junctions, and couplers that help achieve a leak-proof and efficient plumbing setup. Utkarsh Pipes and Fittings is a renowned name in the piping industry, offering a range of pipes and fittings. The quality of SWR pipe fittings is not just about the product finish; basically, it is about how the product performs under extensive temperature changes and prolonged use. Utkarsh Pipes manufacturer follows this comprehensive testing protocol that ensures pipes are: Dimensional Accuracy: Accurate dimensions are essential for smooth installation and leak-proof joining. The correct size of SWR pipes and fittings ensures seamless connection with soil pipe fittings, eliminating the risk of misalignment or leakage. A trusted manufacturer follows standardized measurements as IS: 13592 (for SWR pipes), and 14735 (fittings), which check the parameter for: Outer and inner diameter The thickness of the wall uniformity Socket and spigot fitment Tolerance levels for manufacturing consistency Pressure Bearing Capacity: Even though SWR pipes means non-pressure applications, seldomly back pressure or a blockage situation can build internal stress. Utkarsh Pipes hydrostatic pressure ensure no cracks, deformities or failure occur under load ensuring long-term durability of pipes. Impact Strength: Pipes and SWR fittings often undergo rough handling during transportation and installation. Poor quality product may crack or break in a minor situation. Utkarsh Pipes ensure toughness and resilience, even in rough or load-bearing conditions. UV Stabilization: For outdoor applications or exposed plumbing, UV resistance is non-negotiable. A consistent sunlight exposure can make pipes brittle and prone to breakage. Utkarsh Pipes UV stabilizer components and test the pipes under accelerated weathering conditions to ensure they meet SWR pipes specifications Chemical resistance: Drainage waste and disposal waste systems often encourage corrosive and chemically active substances. Utkarsh Pipe and Fittings manufactures SWR pipe with a high-quality alkaline exposure test, which ensures performs well in industrial waste management. Leak-Proof Testing: Leakage is one of the major concerns in plumbing failure. A rigorous checking for leak-proof joints through air pressure or water tightness testing. This guarantees safety hygiene and maintenance free performance over time. Heat Resistance: Hot wastewater from kitchen or industrial units can lead to the softening, deformation, or cracking of low-quality SWR pipes. This not only affects the flow efficiency but also compromises the structural integrity. Utkarsh Pipes ensures that its SWR pipes and fittings are manufactured with heat-stable compounds and undergo thermal endurance testing and compliance with IS13592, which ensures high temperature discharge conditions. Utkarsh Pipes has an outstanding reputation for quality assurance, product innovation, and customer trust. The range of SWR fittings using state-of-the-art extrusion technology is extended across all vital parameters mentioned. IS certified SWR solution Easy installation with leakproof joining Resistance to weather and chemicals Long service life with minimal maintenance Choosing a trusted SWR pipe manufacturer goes beyond product pricing. It’s about quality, consistency, and compliance with industrial standards. Selecting Utkarsh Pipes, you are investing in durability, safety, and long-term performance in plumbing infrastructure.A Quick Look at SWR Pipes and Fittings

Why Do Testing Parameters Matter?

Why Choose Utkarsh Pipes for SWR Pipes and Fittings

Wrapping Up

What Are the Environmental Advantages of HDPE Pipes?

Jul 24, 2025

Eco-friendly infrastructure is not just a trend; it is a necessity in today’s development landscape. Among modern piping solutions, HDPE (High-Density Polyethylene pipes) offers a powerful combination of durability, sustainability, and performance. Known for their durability, efficiency, and eco-friendly performance, these pipes are widely used in various areas to function. This is the go-to choice for water supply, sewage, irrigation, and industrial applications. This blog explores the environmental advantages of HDPE pipes, shedding light on how they support sustainable development goals, reduce ecological impact, and promote cleaner resource management. Whether you are a contractor, an engineer, or a decision maker in a project. This article will help you to understand why HDPE pipes are the smarter, greener alternative in today’s market. Leak Free Performance: One of the biggest benefits of using HDPE pipes is their ability to create a leak-proof system; the fusion welding between the pipe joints is completely sealed. Unlike other pipes, which depend on mechanical fittings that loosen or leak over time. Corrosion-free: Compared to traditional pipes, rusting and scaling, or reacting with chemicals in the water and soil. HDPE products avoid all of that. They don’t corrode or degrade, even in tough times or rough environmental conditions. Long-term Durability: HDPE pipes are engineered for a service life ranging from 50-100 years, depending on operating conditions such as temperature and chemical exposure. This exceptional longevity significantly reduces the need for frequent replacement, minimizing lifecycle cost and environmental impact. Low Carbon Footprint: HDPE pipes are highly energy efficient across their entire lifecycle, from manufacturing to on-site installation. Their lightweight nature makes them easier to transport and the production process uses less energy. Unlike conventional material, HDPE requires less energy to produce its lower melting points and streamlined fabrication process. Frequent repairs and replacements not only increase project cost but also cause unnecessary disruption to the environment, such as soil disturbance, traffic blockages, and resource wastage. HDPE pipes' durability and flexibility require minimal intervention over decades. For both public utilities and private infrastructure developers, less strain on the environment and more cost-effective project planning. Making them a practical and eco-conscious choice for both public and private projects. Backed by five decades of market presence, Utkarsh HDPE Pipes and Fittings is a preferred choice for contractors, EPC companies, government projects, and infrastructure developers. Our focus on innovation, eco-conscious manufacturing, and client-centric service sets us apart from the crowd. BIS-certified Products Environmentally friendly production process Customised HDPE pipe solution Trusted by suppliers and consumers HDPE pipes offer far more than just fluid transportation; they deliver a sustainable, long-term solution for modern infrastructure. Their environmental advantages include leak-proof performance, low energy consumption, corrosion resistance, and recyclability, making them a superior alternative to conventional piping materials. Partnering with Utkarsh Pipes and Fittings to build greener, smarter, and more resilient systems for the future. Built For Sustainability: How HDPE Pipes Make a Difference

Reduced Maintenance is Equal to Lower Environmental Impact

Why Industry Leaders Trust Utkarsh Pipes

Utkarsh Pipe’s Key Features:

In Conclusion

FAQ:

Are HDPE pipes recyclable after use?

Yes, HDPE pipes are 100% recyclable. Once they fully utilise the lifeline, they can be reprocessed. This helps reduce plastic waste and supports circular economy practice, making it an environmentally responsible choice.How do HDPE pipes reduce water wastage?

HDPE pipes' key advantage is the use of fusion welding to form leak-proof joints. This seamless jointing technology eliminates the common leakage issues found in the conventional piping system. Unlike a traditional piping system.What makes HDPE pipes better than PVC or GI pipes?

HDPE pipes outperform PVC and GI pipes in terms of recyclability, joint integrity, and lifecycle energy consumption. Unlike GI don’t rust, and PVC don’t release harmful chemicals during disposal.

How Do Riser Pipes Work in a Borewell Setup?

Jul 17, 2025

Borewells have become a dependable solution for accessing clear groundwater, especially in areas where the regular water supply falls short. But the efficiency of a borewell doesn’t just depend on how deep it goes- it largely hinges on the components used during borewell pipe installation, particularly the riser pipe. In this blog, we will dive deep into understanding how riser pipes work in a borewell setup, why they are crucial, and how choosing the best borewell pipes can make a lasting impact on your water system performance. A riser pipe, also known as a column pipe, is a vertical pipe that connects the submersible pump (which is placed deep in the borewell) to the surface delivery point. It plays a vital role in lifting water from the underground aquifer to the ground level. In simple words, the riser pipe is considered as the backbone of the borewell setup—it carries water all the way from deep underground to where it is needed. Understanding the borewell riser pipe function is essential to ensure a smooth water supply system. This is how a borewell functions: Water Transportation: Once the submersible pump starts working, it pushes water into the riser pipe. The pipe turn delivers that water to the top. The quality and material of the pipe ensure minimal friction, pressure loss, and leakage. Withstand High Pressure: Riser pipe must withstand high water pressure, especially in deep borewells. They are built to resist pressure and give structural support to the pump and the weight of the water column. Vibration Absorption: Submersible pumps run for long hours; that consistent operation creates a lot of vibration. A well-designed riser pipe helps to absorb these vibrations, which not only protects the pump but also helps the entire system to last longer. Corrosion Resistance: Since ground water often contains minerals and chemicals, it can wear down regular pipes over the period. Therefore, using a high-quality corrosion-resistant riser pipe is important; they are built to last and also reduce the maintenance cost. A successful borewell pipe installation requires a careful selection of materials and precision engineering. Here is what you need to consider: Pipe Materials: PVC and uPVC pipes are commonly preferred for their non-corrosive nature and long life. Pipe Dimension and Thickness: These should match the pump’s capacity and borewell depth Joint Fittings: Leak-proof and pressure-resistant joints ensure a stable water column. Installation Depth: The riser pipe must reach just above the pump and be aligned correctly for efficient water flow. Using the best borewell pipes is not just a matter of quality; it's about reliability, safety, and cost-effectiveness in the long run. At Utkarsh Pipes and Fittings, we provide advanced uPVC column pipes specially designed for borewell applications. Here’s why Utkarsh Pipes should be considered as the first choice: Corrosion-Free Pipes High-pressure handling capacity Leak-proof joints High load-bearing capacity IS-certified product Riser pipes might not grab much attention, but they are absolutely vital in any borewell setup. They take on the heavy task of lifting water from deep underground and supporting the entire pump system. Therefore, it is important to choose the best borewell pipes and get the borewell pipe installation done by a professional. Trust Utkarsh Pipes and Fittings—India’s leading name in water management solutions. Designed for high performance and durability.What are Riser Pipes in a Borewell?

Borewell Rise Pipe Function: Why They Are Important?

Key Factors to Consider During Borewell Pipe Installation

Why Choose the Best Borewell Pipes?

Wrapping Up:

How to Prevent Garden Pipe Leaks and Cracks in Harsh Weather

Jul 17, 2025

A leak-proof garden pipe is a must-have when it comes to maintaining a beautiful garden, especially in the extreme heat, cold, or heavy rains. With the right maintenance tips and by choosing the right quality pipes from a trusted pipe manufacturer can easily prevent damage and extend the lifespan of your garden pipe. Harsh climate can wreak havoc on the material integrity of garden pipe. These are the few common reasons: UV Radiation: Prolonged exposure to the sun weakens the pipe’s outer layer Freezing Temperature: Water inside the pipe expands when frozen, leading to a crack. Excessive Heat: Heat softens the pipe material, making it more loose-fitting and leading to cracks. Improper Storage: Leaving the pipe tangled, kinked, or exposed can cause deformation. Regular care and smart usage can help you avoid leaks and extend your pipes usability. These are some important garden pipe maintenance tips: Choose Weather-Resistant Pipes: Invest in the best garden pipes for harsh weather, pipes that are UV resistant, flexible, and reinforced. High-quality PVC hose pipes from Utkarsh Pipes and Fittings are built to withstand all weather conditions, offering durability and high performance. Store Pipes Properly: Always drain the pipe completely and roll it loosely after use. Store in a shaded place or, preferably, indoors in a pipe hanger to prevent damage. Avoid Sunlight Exposure: Expose your pipe in a shaded area because constant UV exposure degrades material faster, especially PVC base pipe. Use Pipe Stands and Clips: Instead of laying the pipe directly on the ground, especially in areas prone to sharp rocks or high traffic, use pipe clips or stands. This prevents abrasion and punctures Install Nozzles and Shut-off Valves: Adding a good-quality nozzle or a shut-off valve at the end of the pipe helps control water flow and prevent pressure buildup, which causes leaks over time. Warning Signs of a Damaged Garden Pipe Over time, every best pipe needs replacement after long use. Identifying early signs of damage can help avoid water wastage and system inefficiencies. These are some of the most common indications that a garden pipe needs to be replaced. Persistent leaks despite patching Soft or brittle spots along the length Discoloration or UV damage Reduced water pressure due to internal wear At the time of replacement, it’s worth choosing a pipe that won’t let you down. Utkarsh Pipes and Fittings are built to handle tough weather, stay flexible, and deliver lasting strength, making them reliable for any garden setup. Utkarsh Pipe and Fittings is one of the leading garden pipe manufacturers in India, offering a premium quality solution. Our pipes are: Made with quality raw materials Weather- resistance with anti-crack formula Flexible, kink-free, and easy to handle Available in multiple sizes and thicknesses Whether you are a home gardener or a professional botanist, Utkarsh Pipes and fittings offers the best garden pipes for harsh weather, designed to perform under pressure and save your investment. Extreme weather should not disrupt your gardening joy or irrigation plans. With the help of these simple gardening pipe maintenance tips and investing in premium quality from a reliable pipe manufacturer like Utkarsh Pipe and Fittings, you can simply keep your pipe crack-free and fully functional for years. Need help choosing the right pipe for your needs?Why Garden Pipes Crack in Harsh Weather?

Essential Garden Pipe Maintenance Tips

Why Choose Utkarsh Pipes For Gardening?

Wrapping Up

Contact Utkarsh Pipes today and explore our range of pipes, which are weather-resistant and eco-friendly.

Understanding Riser Pipe Design Parameters and Engineering Considerations

Jun 26, 2025

For every water transportation system or underwater pump, riser pipes are the make-or-break factor. Such pipes are specifically made to carry water from deep underground sources to the top and provide a smooth connection while maintaining strength, dependability, and durability. Among industry giants, Utkarsh Pipes & Fittings is one such reliable manufacturer providing high-tech riser pipe solutions. From their advanced materials to state-of-the-art engineering, their riser pipes are designed to serve high-end industry expectations. This blog discusses the design specifications and engineering factors that go into riser pipes, highlighting the characteristics, spec requirements, and far-reaching applications of Utkarsh's products. We'll also emphasize how appropriate riser pipe installation and riser protection contribute to long-term performance. Riser pipes or column pipes are pipes that run vertically and are employed to connect submersible pumps to the ground surface. They are a vital component of borewell systems, which provide smooth water supply while taking care of the weight of the pump and the high pressure. Riser pipes also safeguard infrastructural items such as roads with huge fills to ensure that such spaces remain stable and intact. Being able to support water pressure and pump weight. Protection against environmental conditions such as corrosion and scaling. Conservation of a steady, leakage-free flow of water. Sustaining operations in deep depths or difficult environments. The performance of a riser pipe is highly dependent on its design, material, and correct installation. Utkarsh's riser pipes stand out in all these regards, making them best suited for a wide range of applications. Utkarsh pipes & fittings has become a top riser pipe supplier by integrating high-quality material, modern manufacturing techniques, and strict quality control. This is a summary of the key features of their riser pipes: 1. Best Material Composition High tensile strength for supporting heavy loads. Resistivity to corrosion, so the pipes can be used in alkaline as well as acidic conditions. Durability against wear and tear over extended use. 2. Innovative Thread Design The pipes feature square threads with male and female connectors, designed to: Provide a secure and smooth fit. Ensure leak-proof joints with industrial-grade rubber sealing rings. Minimize damage from pump vibrations, extending pipe life. 3. Technical Durability Utkarsh riser pipes undergo rigorous design and testing: They can safely withstand pump weight, water pressure, and additional shocks. Depth capabilities for various pipe types enable installation in jobs from 300 feet to more than 1200 feet. 4. Smooth Interior Surface Smooth internal finish of the pipes minimizes the chance of scale deposition, providing good water flow while reducing the frequency of maintenance. 5. Lightweight Construction Utkarsh riser pipes are light, making it easy to transport and install quickly without affecting durability or strength. 6. Built-in Riser Protection Utkarsh combines qualities such as galvanic and electrolytic erosion resistance, which improves the performance of the pipe under adverse conditions. The sealing rings, which are made of industrial quality, also contribute to the suitability of such pipes for prolonged use. Installation of riser pipes is important to ensure the effectiveness and durability of borewell and pump systems. Following are some important considerations for engineers to keep in mind: Depth and Pressure Utkarsh riser pipes come in designs according to depth needs: V4 Pipes: 300 feet or less. Medium Pipes: 400 feet or less. Standard Pipes: 850 feet or less. Heavy Pipes: More than 1200 feet. All are designed to manage respective water pressure and pump weight efficiently. Premium rubber sealing rings provide: Leak-proof performance, especially under high pressure conditions. Absorption of vibration caused by pumps, minimizing pipe wall stress. Compatibility with the environment Utkarsh riser pipes can be used in both acidic and alkaline conditions, which makes them useful for a wide range of tasks, including irrigation, industrial installations, and home water supply. Ease of Transportation and Installation Lightweight building of the pipes makes logistical issues easier to handle, and their compact handling mechanism ensures quicker setup. With correct riser pipe installation procedures, systems can be made to deliver maximum performance with minimum downtime. The flexibility of Utkarsh riser pipes renders them suitable for various industries:Why Riser Pipes Are Important in Engineering Systems

Primary Duties of Riser Pipes:

Characteristics of Column Riser Pipes

Utkarsh pipes are constructed from high-grade and high-strength imported additives. This material provides:Engineering Considerations for Riser Pipe Installation

Applications of Riser Pipes

Riser pipes allow water to be transported efficiently for irrigation, enabling sustainable agriculture.

- Chemical Industry

Riser pipes transport corrosive chemicals and chlorides in a safe manner while retaining integrity despite harsh conditions.

- Municipal Systems

Riser pipes provide uninterrupted flow of water systems, particularly in the supply of potable water or the management of sewage.

- Construction and Infrastructure

They play a crucial role in construction works, offering riser protection for buildings with tall fills.

- Submersible Pump Systems

Engineered for high-pressure applications, these pipes are a reliable option in residential, commercial, and industrial borewell setups.

Selecting the Right Riser Pipe

Selecting the appropriate pipe is based on considerations such as:

Installation depth.

Water pressure and discharge rate.

Environmental factors (acidic or alkaline).

Application-specific requirements.

When you buy a high-end riser pipe from Utkarsh pipes & fittings, you can be sure that it will work well, last a long time, and be cheap. Because they last a long time, don't leak, and are easy to install, their pipes are a smart choice for any project.

In conclusion

The majority of water management networks are built around riser pipes, and Utkarsh Pipes & Fittings is a model of excellence in this area. With high strength materials, sealed leak proof joints, and state of the art corrosion and scaling protection, their riser pipes are made to satisfy even the most exacting specifications. Utkarsh pipes & fittings offer dependable performance for many years in submersible city applications or large-scale irrigation projects.

How Our CPVC Pipes Solved a Major Industrial Plumbing Challenge

Jun 24, 2025

To ensure maximum operational efficiency, safety, and long-term durability, an industrial plumbing system is selected. CPVC (Chlorinated Polyvinyl Chloride) pipes and fittings have emerged as a one-stop solution for different industries. Due to empowering features like robust structure, chemical resistance, and versatile adaptability. This piece of content would help you to understand the key advantages of using CPVC in industrial sectors and way out to mitigate the challenges with CPVC plumbing fittings. In this demand and supply eco-system, efficiency and durability are two non-negotiable features. With 5 decades of experience, Utkarsh-Pipes and Fittings stepped in with robust and lasting solutions, leveraging high-performance CPVC plumbing fittings. Utkarsh is actively transforming into a resilient and low-maintenance network-setting a new standard for industrial plumbing solutions. The plumbing network was traditionally built with metal piping, which deteriorated over the time due to constant exposure to high temperatures, UV rays, and chemical-laden fluids. Over the time it causes leakage, which puts the company at high maintenance costs. This complexity of the system demanded a sustainable solution that would be both heat-resistant and chemically stable, without compromising the existing layout. A wide range of industries rely on CPVC plumbing fittings for their strength, chemical resistance, and ability to perform under high temperatures. These fittings are the key component in delivering efficient and durable industrial plumbing solutions, especially where reliability and safety are non-negotiable. Industries that frequently use CPVC pipes and fittings include: Chemical Processing Units Food and Beverage Industry Pharmaceutical Manufacturing Textile and Dyeing Plants Pulp and Paper Industry Water Treatment Industry Commercial and Residential Complexes Hospital and Healthcare Facilities Hotels and Hospitality Sector The industrial demand for plumbing infrastructure needs a wider range of features to mitigate the unique challenges of industrial applications. These are the following reasons why CPVC stands out in industrial plumbing solutions: High Thermal Resistance: CPVC can handle hot fluid up to 93 degrees celsius, making it ideal for steam lines, hot water supply, and high-temperature industrial applications. Superior Chemical Resistance: The non-reactive nature makes CPVC plumbing fittings suitable for transporting acids, alkalis and corrosive fluid without degradation. Smooth Inner Surface: Minimizes friction and prevents scaling or clogging, ensures good flow, and reduces the maintenance time and cost. Durable and Flame Retardant: CPVC is self-extinguishing and maintains structural integrity under extreme conditions, enhancing workplace safety. Easy Installation: Lightweight design and solvent weld joining allow faster and leak-proof installation, reducing labour time and cost. Industrialists who are looking to upgrade their industrial plumbing solutions, Utkarsh Pipes and Fittings offers a perfect solution with the combination of performance, longevity, and value, making it an ideal choice for industrial plumbing solutions. Utkarsh CPVC manufacturer uses advanced technology and adheres to both national and international standards, including ASTM D 2846 & ISI 15778 certified pipes and fittings. These are some standout features that makes CPVC range the first choice for industries: High Heat Tolerance Corrosion Resistance Fire Retardant Smooth Internal Surface Wide Range of Fittings By combining all these amazing features with our proactive services and installation all over India. Utkarsh Pipes and Fittings continues to set a benchmark in industrial plumbing solutions. Industrial projects demand much more than just products - they require reliability, performance, and a partner who understands long-term value. This field Utkarsh Pipes and Fittings, stands as a testman for all kinds of piping and fittings delivered in all fronts.Major Challenge of Industrial Plumbing Solved by CPVC Plumbing

Which Type of Industry Approach CPVC Pumping Fittings

These sectors benefit significantly from the advanced engineering of CPVC plumbing fittings, making them a reliable choice for modern industrial plumbing solutions that demand long-term sustainability with minimum maintenance.Withstanding Industrial Demands: How CPVC Is Engineered for Performance

Why Utkarsh CPVC Pipes are Ideal for Industrial Applications:

Final Thoughts

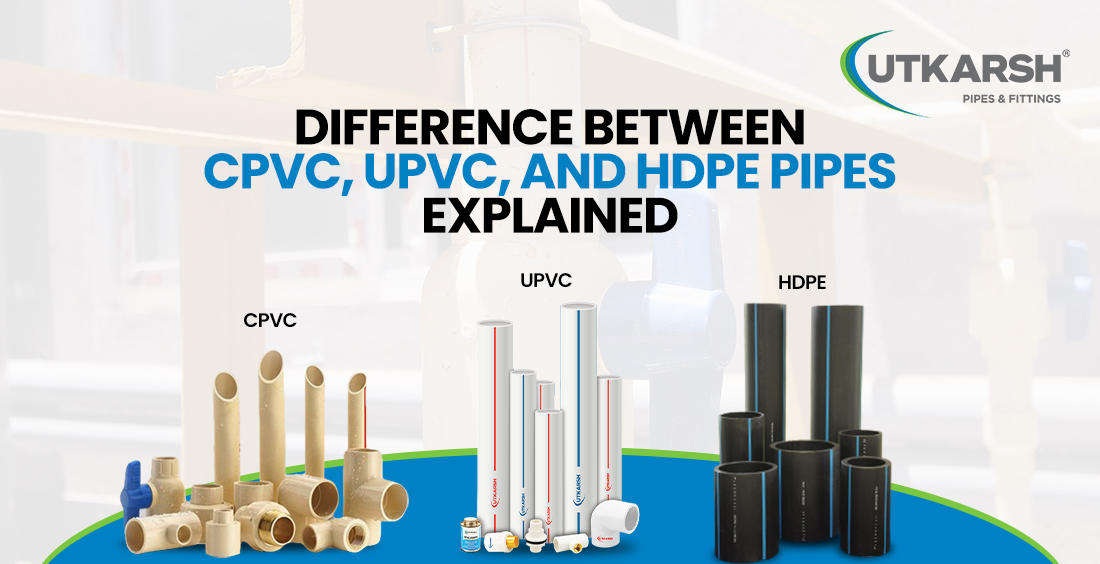

Difference Between CPVC, UPVC, and HDPE Pipes Explained

Jun 24, 2025

Ever wonder what’s hidden behind your walls, carrying water to your faucet, or in your bathroom, managing waste? The unsung heroes of any building are its plumbing pipes. Choosing the right type is important for a long-lasting, efficient, and safe water flow. Today, plastic pipes are often the go-to choice, replacing older metal options. They are lighter, resist rust, are easier to install, and are generally kinder to your budget. But with names like CPVC, UPVC, and HDPE floating around, it can get confusing. Let’s break down the difference between these common types of plastic pipes for plumbing in simple terms.

Plastic pipes have become the preferred choice, and they are steadily replacing old-school metal pipes. CPVC, UPVC, and HDPE are now the most common terms preferred for any piping solutions.

Why Plastic Pipes Rule Modern Plumbing

Some of the best features why these plumbing pipes have become so popular

- No Rust: Unlike iron or steel, plastics don’t corrode, ensuring cleaner water and longer life.

- Light Weight: Makes them much easier to transport, handle, and install.

- Smooth Inner Surface: Their smooth inner wall means less friction, allowing water to flow freely and efficiently.

- Chemical Resistance: They handle common water treatment chemicals very well

- Cost-Effective: Generally more affordable than metal alternatives.

Understanding the Different Types of Plumbing Pipes

1. CPVC (Chlorinated Polyvinyl Chloride) Pipes

The main feature of CPVC pipes is to tolerate heat, which is a limitation in the case of PVC. The “C” stands for Chlorinated, which is significant to tolerate the heat. Therefore, it is suitable for both hot and cold domestic water uses.

Common Uses: Entire domestic hot and cold water supply system within buildings, industrial liquid handling.

Key Benefits:

- Heat Resistance: It can withstand temperatures up to 200 degrees Fahrenheit, ideal for a hot water supply.

- Corrosion Free: Does not rust easily like metal pipe also guarantees long-lasting performance.

2. UPVC (Unplasticized Polyvinyl Chloride) Pipes

It is also known as Rigid PVC. The ”U” means no plasticizers (softening chemicals) are added.

Key Features:

- Super Strong and Stiff: Even more rigid and durable than standard PVC. Excellent for structural pressure.

- Weather Suitable: High resistance to sunlight (UV rays) and weathering, making it ideal for outdoor use.

- Chemical Resistance: Handle corrosive elements exceptionally well.

Common Uses: Main underground cold water supply lines, especially where high pressure or external exposure is a factor, industrial piping, and waste systems.

3. HDPE (High-Density Polyethylene) Pipes

Known for their flexibility and toughness. Usually black with distinctive raised stripes.

Key Features:

- The Flexibility: Can bend or curve, making it great for navigating around obstacles or uneven terrain without needing many fittings.

- Leak-Proof Joints: Uses heat fusion to weld joints, creating seamless, incredibly strong, leak-proof connections.

- Impact Resistance: Tough and resistant to cracks, even in freezing conditions.

- Corrosion and Chemical Proof: Excellent resistance to a wider range of chemicals and abrasion.

Common Uses: Main underground water supply lines (municipal and rural), gas distribution, slurry and mining pipelines, agricultural irrigation, and marine outfalls. Less common inside the house for standard hot/cold supply compared to CPVC.

PVC vs. CPVC vs. UPVC vs HDPE: A Quick Comparison

Features

CPVC

UPVC

HDPE

Best For

Hot and Cold water inside

Cold water, Outdoor/High Pressure

Underground mains, Gas, and Flexible needs

Temp. Range

Hot and Cold water

Cold water only

Hot and Cold water

Flexibility

Rigid

Very Rigid

Flexible

Key Strength

Hot Water Capability

Weather/UV Resistance

Impact Resistance, Leak-Proof Joints

Main Uses

Indoor Water Pipes

Outdoor Mains, Drainage

Underground Utilities

Features | CPVC | UPVC | HDPE |

Best For | Hot and Cold water inside | Cold water, Outdoor/High Pressure | Underground mains, Gas, and Flexible needs |

Temp. Range | Hot and Cold water | Cold water only | Hot and Cold water |

Flexibility | Rigid | Very Rigid | Flexible |

Key Strength | Hot Water Capability | Weather/UV Resistance | Impact Resistance, Leak-Proof Joints |

Main Uses | Indoor Water Pipes | Outdoor Mains, Drainage | Underground Utilities |

How to Choose the Right Pipe

There is no single “best” pipe. The right choice depends entirely on your project:

- Temperature: CPVC is essential for indoors as it is suitable for both hot and cold water. UPVC, or HDPE, is suitable for cold water.

- Location: CPVC is recommended for water flow. For outdoor exposure to the sun, UPVC is an excellent choice. And for buried underground, HDPE, UPVC are strong contenders.

- Pressure: To resist high pressure, UPVC or HDPE are excellent choices. Standard household uses can be done with CPVC, which works well.

- Flexibility: HDPE shows the major advantage of flexibility. Toughness and rigidity can be found in CPVC and UPVC.

- Leak Proof: HDPE is the answer for leakproof and comfortable welded pipe connections.

Trust the Expert for Quality Flow:

Understanding these different factors empowers you to make informed decisions, whether you are a homeowner planning a renovation or a professional specifying materials. Using the right type of plastic pipes for plumbing ensures safety, efficiency, and longevity for your plumbing system.

When quality and reliability are non-negotiable, choosing a pipe from a reputable pipe manufacturer is an essential choice to make. At Utkarsh Pipes and Fittings, we take pride in manufacturing a wide range of high-performance CPVC, UPVC, and HDPE pipes designed to meet diverse needs and stringent quality standards. Utkarsh pipes use premium materials and advanced processes to deliver pipes you trust for every application-from the main supply lines to your kitchen sink.

Explore our range and find the perfect pipe solution for your next project. Over the last five decades, Utkarsh Pipes and Fittings has been a partner for reliable, efficient, and long-lasting plumbing systems in Kolkata.

Top Questions to Ask Garden Pipe Manufacturers Before You Buy

May 27, 2025

Gardening becomes effortless when your tools work for you, including your choice of pipe. A flexible garden pipe can add to the smoothness of watering your plants by making it hassle-free and efficient. Asking the proper questions and getting the correct answers from the garden pipe manufacturers can help save you a lot of frustration in the future. Making the right decision out of so many options in the market becomes easier when you know what to look for. Here’s a complete garden pipe buying guide with the top questions you should ask to ensure you bring home the best. Out of all the guides available, this is one question that gets avoided the most. The durability and flexibility of the pipe are determined by the raw material it is made of. Typically, pipes made from virgin-grade plastic or good quality PVC tend to hold up better in terms of durability and efficiency. On the other hand, low-grade plastic pipes tend to crack, melt or stiffen over time, especially under extreme weather. Having the right garden pipe material can save you a lot in maintenance. India experiences a wide range of temperatures. So, ask if the flexible garden pipe can handle both scorching heat and chilly winters. Pipes that become stiff in winter or soften in summer are not ideal. Reliable garden pipe manufacturers will provide pipes that stay flexible and usable across all weather conditions. Twisting, kinking, or tangling is a common issue with low-quality pipes. Ask manufacturers how well their flexible garden pipe maintains shape and usability after repeated use. Good pipes should bounce back into shape without kinking. This is especially important if you have a larger garden that requires regular movement of the pipe. Pipe thickness determines durability. Thin pipes may be lighter but tend to wear out faster. Thicker pipes are generally more robust and longer-lasting. However, they shouldn’t be too heavy to carry around the garden. A reliable garden pipe buying guide would always suggest striking a balance between weight and durability. Ask if the pipe is UV-stabilized. Pipes exposed to sunlight every day should have protection against fading and weakening. UV protection ensures your flexible garden pipe maintains its strength and color even after years of outdoor use. It’s always wise to ask about product assurance. Good garden pipe manufacturers back their products with a clear warranty or quality guarantee. This shows confidence in their product and offers you peace of mind. Before you wrap up your decision, consider Utkarsh Pipes & Fittings, one of the leading garden pipe manufacturers in India. Their pipes are proudly made in India with a vision of building a greener future. These all-weather pipes can withstand extreme temperature variations without melting or becoming brittle. Made from superior garden pipe material, they resist twisting and tangling—even after extended periods of non-use. Plus, their vibrant colors don’t fade, thanks to high-quality pigments. With a diverse product range and dependable performance, Utkarsh stands out as a trusted name in every garden pipe buying guide. Choosing the right flexible garden pipe means asking the right questions before making a purchase. From material quality and weather resistance to UV protection and durability, each factor plays a role in how your pipe performs daily. Don’t settle for less—talk to trusted garden pipe manufacturers and let your garden thrive with the right tools by your side.1. What Material Is Used to Make the Garden Pipe?

2. Is the Pipe Resistant to Temperature Changes?

3. How Flexible and Tangle-Free Is the Pipe?

4. What Is the Pipe’s Wall Thickness and Weight?

5. Does the Pipe Have UV Protection?

6. Is There a Warranty or Guarantee Provided?

Why Choose Utkarsh Pipes & Fittings?

Concluding Remark

How uPVC Pipe Ensure Leak-Free Plumbing Systems

May 27, 2025