PVC casing pipes are widely used in borewell applications for the distribution of hard water, including salty, sandy, or chemically aggressive water, ensuring reliable performance in various industrial environments.

As the top producer of PVC Casing Pipes in India, we provide a comprehensive selection of these pipes that guarantee smooth and effective water delivery systems.

As a trusted PVC casing pipes supplier and one of the leading PVC casing pipes supplier & manufacturers, we ensure that every product meets stringent quality benchmarks. Our pipes are engineered to serve diverse industrial and agricultural needs.

We choose top-grade PVC compound to manufacture our range of PVC boring pipes and casing pipes, ensuring robust quality control measures and competitive PVC casing pipe prices.. Each product undergoes comprehensive testing, including:

Along with ensuring adequate protection and filtration against debris and sediment for uncontaminated water extraction, our extensive range of PVC casing pipes - including shallow, medium, deep and strainer casings - makes sure optimum performance across several well depths & conditions, making it the best casing pipe for borewell.

We take great pride in being the most trusted PVC casing pipe manufacturers and throughout the world, especially for our solutions for the best casing pipe for borewell, thanks to our many years of experience and technical know-how. We are able to always surpass customer expectations because of our everlasting dedication to quality and innovation-first approach.

As the top producer of PVC Casing Pipes in India, we provide a comprehensive selection of these pipes that guarantee smooth and effective water delivery systems.

PVC Casing Pipes – Durable Solutions from Expert PVC Casing Pipe Manufacturers

Meticulously crafted from high-quality polyvinyl chloride (PVC), our PVC casing pipes are the optimal choice for various applications, particularly in borewells and regions with highly collapsible soil. Renowned for their versatility and durability, these pipes provide stability and reliable performance in sandy-loose soil and silt conditions. As a leading PVC casing pipe manufacturer, we ensure that our products meet stringent quality standards, making them ideal for diverse industrial applications and the best pipes for borewells.As a trusted PVC casing pipes supplier and one of the leading PVC casing pipes supplier & manufacturers, we ensure that every product meets stringent quality benchmarks. Our pipes are engineered to serve diverse industrial and agricultural needs.

We choose top-grade PVC compound to manufacture our range of PVC boring pipes and casing pipes, ensuring robust quality control measures and competitive PVC casing pipe prices.. Each product undergoes comprehensive testing, including:

- Density testing,

- Tensile strength testing,

- Impact resistance at 0 degrees Celsius,

- Vicat softening temperature evaluation

- Water quality impact testing.

Along with ensuring adequate protection and filtration against debris and sediment for uncontaminated water extraction, our extensive range of PVC casing pipes - including shallow, medium, deep and strainer casings - makes sure optimum performance across several well depths & conditions, making it the best casing pipe for borewell.

We take great pride in being the most trusted PVC casing pipe manufacturers and throughout the world, especially for our solutions for the best casing pipe for borewell, thanks to our many years of experience and technical know-how. We are able to always surpass customer expectations because of our everlasting dedication to quality and innovation-first approach.

-

68000

Production Capacity

-

44000

Plant Area

-

5000

Ready Stock

Product Specifications

Get the full specs of our PVC Casing Pipes – built tough, globally trusted, and competitively set with the best PVC casing pipe price in a variety of applications.

Explore the detailed PVC casing pipe specifications, which shed light on the areas of precise measurements, materials, and performance requirements from trusted PVC casing pipe manufacturers for reliable applications.

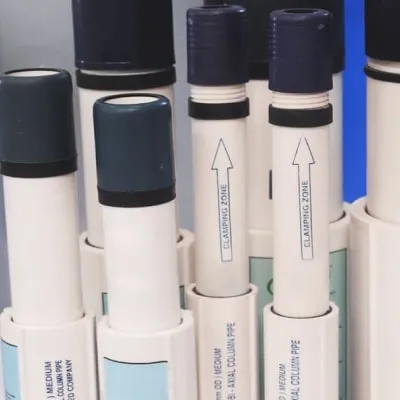

- Pipes :

Casing Medium (CM): 40mm (1 ½ ") to 300mm (12") Casing Shallow (CS): 150mm (6") to 300mm (12") Casing Deep (CD): 100mm (4") to 400mm (16") SCHEDULE 40 : 100mm (4") to 400mm (16") SCHEDULE 80 : 100mm (4") to 400mm (16") Ribbed Strainers: Ribbed Medium Screen (RMS) - 40mm (1 ½ ") to 175mm (8") - Casing Pipes by Tube Well Depth :

Casing Shallow (CS) Pipe: for wells with depths up to 80 metres (262 Ft) Casing Medium (CM) Pipe: for wells with depths above 80 metres and upto 250 metres (820 Ft) Casing Deep (CD) Pipe: for wells with depths above 250 metres and upto 450 metres (1476 Ft)

- Casing Pipes by Tube Well Depth :

For deep, medium, and shallow borewells Standards: IS 12818-2010, ASTM D-1785

Our PVC Casing Pipes and PVC boring pipe solution are produced by sourcing the best raw materials, adhering to strict industry norms for consistent reliability and quality. As a trusted PVC casing pipe supplier, we ensure every product delivers

- High-Grade PVC for Lasting Durability:

Crafted from premium PVC, our best casing pipes for borewell are designed to deliver long-lasting and reliable water supply solutions, ensuring minimal maintenance and maximum efficiency. - Standards Compliance and PHED Approval:

Our best casing pipe for borewell meets stringent industry standards like ISO, EN, BIS, and more, and are PHED-approved, guaranteeing superior quality and safety. - Diverse Agricultural Solutions:

We offer a range of shallow, deep, and medium, and deep PVC casing pipes and strainers specifically tailored to meet various agricultural needs. This extensive range further reinforce our position as a reliable PVC casing pipe supplier for borewell solutions. - Rigorous Testing for Quality Assurance:

Each PVC casing pipe and PVC boring pipes undergoes stringent testing for density, tensile strength, impact resistance, and water compatibility to ensure exceptional performance and durability.

Know more about the additional features of our PVC Casing Pipes, which include important details about functionality, reliability for a range of applications, and ease in installation.

- Threaded terminals for easy joining:

Each PVC casing pipe is designed for effortless assembly with our threaded terminals, engineered for seamless and secure connections. - Rust-free, chemical-resistant, and durable:

Built to last, our PVC casing pipes are rust-free, chemical-resistant, and engineered for enduring performance in tough conditions. - Non-toxic, preserving water taste:

To ensure purity with non-toxic materials that maintain the natural taste of water without compromise. - Strong and lightweight for easy transport and installation:

All these features come with a highly competitive PVC casing pipe price, ensuring top value without compromising quality.

| BIS License No-5813874 | ASTM D 1785 | DIN 4925 | IS 12818-2010 |

| Casing Medium 40 mm(1 1⁄2') TO 300 mm (12") Wells With Depth From 80 mtrs To 250 mtrs | Casing Shallow 150 mm(6") TO 300 mm (12") Wells With Depth Upto 80 mtrs | Casing Deep 100mm (4") to 400mm (16") Wells With Depth Above 250 mtrs To 450 mtr |

Application Areas

Manufacturing Process

-

Mixing and Cooling

Raw materials and chemicals are fed into a high-speed mixer via an automatic SCADA system using a pre-set recipe. Once the mixture reaches the desired temperature, it is transferred to a cooling chamber and then to the extruder hopper.

-

Precision Feeding

The material is fed into the extruder using a hopper with a gravimetric or volumetric control system for precise measurements.

-

Melting Process

Inside the extruder barrel, the material is heated to approximately 180°C using load (melt pressure) and friction in the twin-screw system to achieve melting.

-

Pipe Formation

The melted material is pushed through a die-head (spider) to form the pipe.

-

Sizing & Cooling

The pipe is calibrated to the correct size using a vacuum sizing tank and then cooled by water in a spray tank.

-

Printing & Finishing

The pipes are printed and cut to length, socketed, and inspected online. Depending on the application, the pipes are threaded and slotted in post-production.

-

Final Inspection & Dispatch

Final inspections by QA are carried out, and the finished pipes are dispatched as per the delivery order (DO).