Column pipes, also known as riser pipes, are essential components in borewells and submersible pump systems. These column pipes are designed to transport water from deep underground sources to the surface, supporting the pump's weight and withstanding high pressure. Mainly used for submersible pumps, Column Pipes are utilised to protect road infrastructure, especially for those with large fills to prevent complete fall. As a leading manufacturer and supplier of column riser pipes, we provide a comprehensive selection of these pipes that ensure smooth and superior performance.

We’re not just any column pipe manufacturer, we’re the name people trust, in India and beyond! With years of expertise and a passion for innovation, we always deliver more than expected. Our uPVC column riser pipes and column riser pipes are built tough, designed to last, and made to handle whatever the job throws at them. Quality isn’t just a promise; it’s what makes us stand out.

Column Riser Pipes: Your Go-To Column Pipe Manufacturer for Robust Solutions

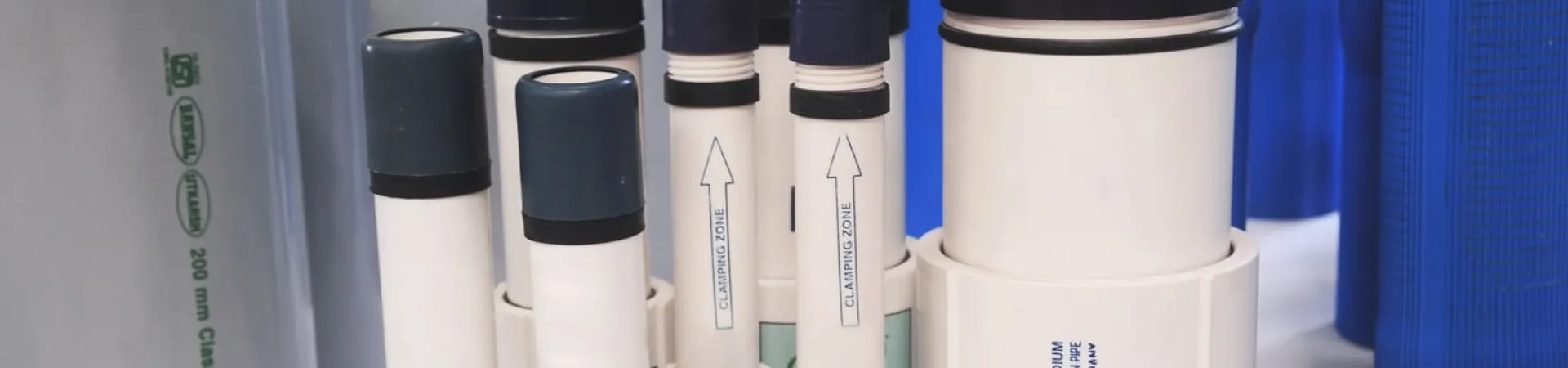

Made with superior uPVC compound, our column pipes feature heavy-duty sealing rings made of certified industrial-grade rubber, guaranteeing long-lasting performance. These heavy-duty sealing rings don’t just keep things leak-proof, they absorb pump vibrations, extend pipe life, and guarantee a hassle-free water supply. Recognized as a reliable column pipe manufacturer in India, we make sure every uPVC column riser pipe is built with top-tier materials from industry leaders, pushing the boundaries of quality and performance.We’re not just any column pipe manufacturer, we’re the name people trust, in India and beyond! With years of expertise and a passion for innovation, we always deliver more than expected. Our uPVC column riser pipes and column riser pipes are built tough, designed to last, and made to handle whatever the job throws at them. Quality isn’t just a promise; it’s what makes us stand out.

- Designed to withstand both galvanic and electrolytic corrosion

- Available in various range

- Adherence to all industry standards

-

44000

Plant Area

-

68000

Production Capacity

-

5000

Ready Stock

Product Specifications

Explore the comprehensive specifications of our uPVC Column Riser Pipes to learn more about how we, as a leading column pipe manufacturer, maintain the highest quality standards for superior performance, toughness, and reliability. Designed for a variety of applications, our pipes, including column riser pipe, ensure durability and efficiency, marking us as one of the most trusted manufacturers and suppliers of uPVC column riser pipes in India.

Discover the technical specifications of our Column Riser Pipes, detailing the exact measurements, materials, and performance standards for reliable use.

- Material:

Premium-quality uPVC and imported additives for high tensile strength. - Standards:

Specially designed and manufactured under stringent quality standards. - Size Range:

Pipes: 1", 1 ¼ ", 1 ½ ", 2", 2½", 3", 4". Female belled threads at one end and male threads on the other end (and/or with separate coupler) Pipes available in 3 metre length with square threads fitted with rubber sealing ring at male threaded end. - Length:

3 metres or as per customer requirement. - Design & Testing

Design: Square threads for high tensile load capacity and leak-proof joints. Testing: Withstands pump, water, and pipe weight with safety factors. Can withstand considerable shocks and jerk load. - Depth Requirements:

V4: Up to 300 feet. Medium:Up to 400 feet. Standard: Up to 850 feet. Heavy:Above 1200 feet.

Known for our excellence as a column pipe manufacturer in India, our uPVC column riser pipes are made with the finest materials, carefully crafted to meet strict industry standards and deliver exceptional reliability and performance.

- Easy to Transport & Install:

Column pipes are lightweight and designed for hassle-free transport and installation, making them ideal for quick setup in borewell systems. - Resistant to Galvanic & Electrolytic Erosion:

Engineered to withstand both galvanic and electrolytic erosion, column pipes are hygienic, eliminate contamination risks, and ensure durability and long-term reliability in harsh environments. - Smooth Inside Surface to Prevent Scale Formation:

The smooth interior of column pipes minimises scale buildup, maintaining efficient water flow and reducing the need for frequent maintenance. - Suitable for Alkaline or Acidic Environments:

uPVC Column pipes are crafted to perform well in both alkaline and acidic environments, offering versatile solutions for diverse applications. - Equipped with High-Quality Rubber Sealing Rings:

Fitted with premium rubber sealing rings, column pipes provide secure, leak-proof connections, ensuring dependable operation in submersible systems. - High Tensile Load Capacity

Utkarsh column riser pipes feature specially designed square threads (male and female) for smooth fitment and refitment, ensuring superior tensile strength to handle high loads effectively. - Cost-Effective Solution

Utkarsh column pipes for submersible pumps offer overall economy, making them a more affordable and efficient option compared to conventional pumps.

Explore about the additional features of our Column Riser Pipes, which include significant details about reliability and functionality for a range of applications as well as ease in installation.

- Availability of range Pipes: 1", 1 ¼ ", 1 ½ ", 2", 2½", 3", 4".

- Thread Types:

Female belled threads on one end. Male threads on the other end. Separate coupler available. - Length: 3 metres.

- Thread Design: Square threads with a rubber sealing ring at the male threaded end.

| Type | Sizes |

|---|---|

| V4 | For 300ft |

| Medium | For 400ft |

| Standard | For 850ft |

| Heavy Above | 1200ft |

| Type | Sizes |

|---|---|

| V4 | For 300ft |

| Heavy Above | 1200ft |

Application Areas

Manufacturing Process

At Utkarsh Pipes, we manufacture every uPVC pipe & fitting with precision, starting from premium raw material selection to advanced manufacturing, multi-stage quality checks, and secure packaging. Decades of expertise and innovation make our uPVC column riser pipes a benchmark for durability and reliability in India.

-

Raw Material Preparation

Raw materials and chemicals are fed into a high-speed mixer via an automatic SCADA system using a pre-set recipe. Once the mixture reaches the set temperature, the compounded material is released into a cooling chamber to cool to a predefined temperature. The cooled compound is then sent to the extruder hopper.

-

Material Feeding

The material is fed into the extruder through a hopper, controlled by a gravimetric or volumetric system for precise measurement.

-

Melting and Mixing

In the extruder barrel, the material is heated to its melting point, around 180°C, through a combination of load (melt pressure) and friction within the twin-screw system.

-

Pipe Formation

The melted material is pushed through a die-head (spider) and formed into a pipe shape.

-

Calibration and Cooling

The pipe is calibrated to the correct size using a vacuum sizing tank and then cooled with water in a spray tank.

-

Printing, Cutting, and Socketing

At the end of the production line, pipes are printed, cut into lengths, and socketed. The pipes undergo online inspection and testing according to standards. They are then sent for post-activity processes, including threading and slotting.

-

Final Inspection and Dispatch

The pipes are subjected to a final inspection by QA. After passing the final checks, they are prepared for dispatch as per the delivery order.